Test: SAM loader wagon

Upgraded tyres improve stability and ease of towing

Upgraded tyres improve stability and ease of towing

Loading height similar to other wagons, not a problem for your average dairy farmers’ tractor

Loading height similar to other wagons, not a problem for your average dairy farmers’ tractor

Scales offer good visibility from the cab but not so good for loading

Scales offer good visibility from the cab but not so good for loading

Clever load-sensing hydraulics makes feeding out evenly easy

Clever load-sensing hydraulics makes feeding out evenly easy

Keeping correct tension on the feed belt helps minimise wear and tear

Keeping correct tension on the feed belt helps minimise wear and tear

Solid, fixed tow hitch and foot, along with stand makes connection to the tractor hassle free

Solid, fixed tow hitch and foot, along with stand makes connection to the tractor hassle free

Grease nipples are labelled and easy to get at, including the axles

Grease nipples are labelled and easy to get at, including the axles

|

|

Upgraded tyres improve stability and ease of towing

|

|

|

Loading height similar to other wagons, not a problem for your average dairy farmers’ tractor

|

|

|

Scales offer good visibility from the cab but not so good for loading

|

|

|

Clever load-sensing hydraulics makes feeding out evenly easy

|

|

|

Keeping correct tension on the feed belt helps minimise wear and tear

|

|

|

Solid, fixed tow hitch and foot, along with stand makes connection to the tractor hassle free

|

|

|

Grease nipples are labelled and easy to get at, including the axles

|

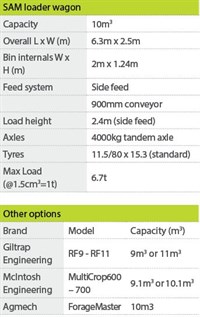

The silage wagon market is saturated here in New Zealand, but Kiwi manufacturers, like Coombridge and Alexander, continue to produce great products that are proving popular on Kiwi farms. This month Mark Fouhy experienced the SAM loader wagon for himself.

Coombridge and Alexander is the manufacturer of the Waikato-based green and gold SAM brand. It produces a range of machinery, including silage wagons — a very competitive product here in New Zealand.

This month I caught up with Willy McKnight, contract milker for Wallace Hall, at Te Miro, near Cambridge, where they've just taken delivery of a new 10-cubic-metre side-feed SAM silage wagon to replace their older one. Hall had already owned SAM equipment for some time, including a single-axle trailer painted in the original red and white company colours, as well as spreaders and his wagon.

The test

The day I arrived for the test the property was relatively dry. The property is made up of 185ha milking platform, 83ha retired bush areas, and 50ha of steeper sidling's and area used as runoff for young stock and supplements. I would describe the ground as undulating, not flat.

McKnight will mostly tow the new 10-cubic-metre SAM with his 6120 John Deere. The day I was there we had Hall's John Deere 6330 loading and pulling the new wagon. The advantages of using the bigger Deere over the smaller one is the bigger mirrors that help you avoid taking any paint off the new machine, plus it handles the extra weight in front of the wagon.

The size of a wagon is important here as the loaded wagon can push the tractor around on the hills. Being sensible, McKnight fed the easy paddock, to lighten the load, before heading off down the steeper end of the farm to feed.

Opting for the lower profile flotation tyres over the standard tyres helps a little, and puts more rubber on the ground to keep the wagon stable and tow better. Having the wheels underneath allows them to get closer without hitting the feed trough, and reduces wastage.

Setting up the wagon for feeding was pretty simple, with holders for the two hydraulic hoses, which are stamped with clear labels showing which line goes to what. Oil flow rate demand is only 40L/min, which even older model tractors should be capable of.

Fixed features and extras

Most SAM wagons are made to the same specification, with a lot of the features farmers want, including side-feed allowing the operator to feed into troughs on feed pads, and easily-accessible grease nipples.

Making the wagons feature-full from the start, rather than adding additional cost to a base model, makes them very cost competitive. All new SAM wagons are now made with a double chassis for fitting with scales.

Making the wagons feature-full from the start, rather than adding additional cost to a base model, makes them very cost competitive. All new SAM wagons are now made with a double chassis for fitting with scales.

Hall chose to have the Iconix scales fitted to his machine, as it's good to know what your loader bucket of maize/silage roughly weighs. Taking the guess work out should help with accuracy of feeding valuable supplementary feed. This makes it easy to split a wagon load into two mobs, without over or under feeding one or the other. I like that the scales are mounted on the wagon, meaning you can load and feed with different tractors. The monitor is mounted in the centre of the wagon for excellent visibility from the cab, and pivots to either side to view while loading. I think it would be good if it were mounted on a pivoting arm which could go to either side of the wagon and be easily seen while loading, without having to back up to see how much you have loaded into the wagon. I like that the monitor comes with both mains and cables for charging from the tractor's internal battery.

The option Hall had fitted was the wider flotation tyres over the standard 11.5/80x15.3. Feeding in the paddocks, these are slightly lower profile, offering better stability, and less compaction with the bigger surface area on the ground.

Servicing/reliability

Servicing and reliability was one of the big reasons as to why Hall replaced his old SAM wagon with the new machine. He'd not had any issues over the 19-plus years of ownership of the first SAM wagon and had only replaced the side-feed belt once and the lift chains just before he sold it to another sharemilker. However, one of the improvements Hall admired was the helpful grease-point labelling and grouping together of the axle pivot points with quality hydraulic type thick lines. There is only one hidden behind the cover for the drive chains, which requires the cover to be removed in order to get to it. Keeping the two floor chains, lift chains, and feed belt tensioned correctly are the main things to keep an eye on. These maintenance jobs can be completed by staff on-farm, rather than requiring specialist service technicians for repair and maintenance and annual servicing like some mixer wagons.

Coombridge and Alexander stocks a comprehensive range of parts for its range of machinery and fully guarantees its products. Hall has found it an excellent company to deal with, and says the back-up service he has received is second to none. Having a good product is one thing, but having excellent customer service will mean the customer will come back, even if it's nearly 20 years later. Hall bought his new wagon through Piako tractors in Morrinsville, but SAM machines can be ordered through a range of dealers around the country.

Verdict

Keeping the wheels moving is vital in any business, and Hall and McKnight understand this all too well, hence why they update equipment to minimise lost time and production due to break downs. Although the old wagon didn't have any issues, they are not adverse to keeping up with technology and opting for the latest models. No doubt if they look after the new green and gold wagon, the same way they did the old one, they'll get another 20-odd years of trouble-free service from it — and the new easy maintenance features will help. One of the standout features for me was the wagon's ability to take scales — the icing on the cake for such a well-built wagon.

Positives

- Good reliable machine, low on-going maintenance costs, simple greasing and checking/adjusting of chain and belt tension is all that is really required

- Well built with stainless steel sides and galvanised components

- Weight is in the chassis

- Excellent paint job

- Designed to take scales, which can be retro-fitted at a later date

Negatives

- The scales mounted on a fixed point in the centre make it hard to see when you are loading

- Handle for floor adjustment is too short to reach from tractor cab with quick hitch, but may be able to reach with a ROPS tractor. Not a big issue if you know what speed you need when you get off to open the gate

For the latest reviews, subscribe to our Farm Trader magazine here.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpg)

.jpg)

.jpg)