Review: Slurryquip umbilical systems

The reeler begins the un-rolling process.

The reeler begins the un-rolling process.

The 9.5m rear dribble bar with 30cm intervals.

The 9.5m rear dribble bar with 30cm intervals.

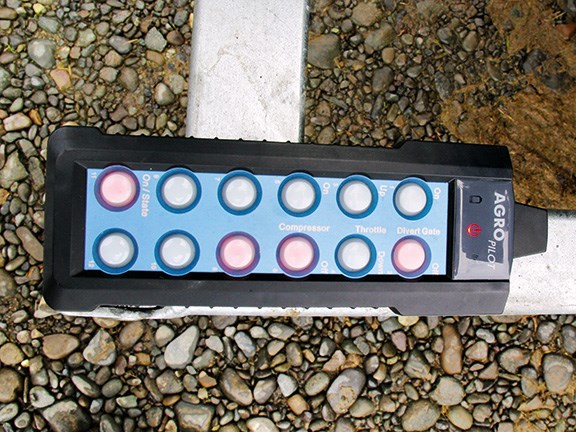

The in-cab remote which controls the throttle robot and diverter gate.

The in-cab remote which controls the throttle robot and diverter gate.

The Storz fittings on this set-up significantly reduces hose damage.

The Storz fittings on this set-up significantly reduces hose damage.

The throttle robot mechanism.

The throttle robot mechanism.

The front and rear reelers are interchangeable. The black cog provides drive for the hydraulic motor.

The front and rear reelers are interchangeable. The black cog provides drive for the hydraulic motor.

The Bauer pump at work.

The Bauer pump at work.

The in-cab monitor with flow rates and cumulative total.

The in-cab monitor with flow rates and cumulative total.

The reelers are un-wound hydraulically and 1500m of pipe can be set up in around 15 minutes.

The reelers are un-wound hydraulically and 1500m of pipe can be set up in around 15 minutes.

The front wheeler can be left on the front linkage or loader depending on your set-up during spreading, or easily unhooked at a headland.

The front wheeler can be left on the front linkage or loader depending on your set-up during spreading, or easily unhooked at a headland.

|

|

The reeler begins the un-rolling process.

|

|

|

The 9.5m rear dribble bar with 30cm intervals.

|

|

|

The in-cab remote which controls the throttle robot and diverter gate.

|

|

|

The Storz fittings on this set-up significantly reduces hose damage.

|

|

|

The throttle robot mechanism.

|

|

|

The front and rear reelers are interchangeable. The black cog provides drive for the hydraulic motor.

|

|

|

The Bauer pump at work.

|

|

|

The in-cab monitor with flow rates and cumulative total.

|

|

|

The reelers are un-wound hydraulically and 1500m of pipe can be set up in around 15 minutes.

|

|

|

The front wheeler can be left on the front linkage or loader depending on your set-up during spreading, or easily unhooked at a headland.

|

Farm Trader headed to the deep south to see the Slurryquip umbilical system in action. Despite the icy temperatures, Jaiden Drought was impressed by what he saw.

As farming – and dairying in particular – intensifies, the amount of effluent created particularly in housing and feedpad situations dramatically increases and the can quickly escalate into a costly issue.

This month we test something of a solution for farmers and contractors in this regard. While not a completely new concept for people, this machine does definitely make life easier for winter time effluent solutions.

I head to Southland to catch up with Eddie Rabbit who owns and runs Rabco Ag. Eddie has the pleasure of dealing with the terrible twosome running Slurryquip; principal owner and proud Irishman Richard Fitzpatrick, and his Scottish sidekick Raymond (Razor) Copland.

Eddie already runs two large Joskin Euro Liner tankers, but needed a solution for the growing demand to lower tank and pond levels during the wet winter months; the alternative option of getting heavy tankers onto paddocks not really being a viable one.

There are three integral parts to the machine. First is the pump, second are the hoses and reelers and third is the distribution method, which in this case is a 9.5m dribble bar.

The pump

Slurryquip prefer Bauer pumps based on their output, reliability and superior build quality, although other popular makes are Doda or Criman pumps which can be supplied if the client wishes.

Regardless of the brand, all pumps are supplied on a galvanised frame, have a primer, shear bolt protected PTO shaft, suction pipe (either 6 inch or 8 inch) and a set of discharge valves. The pumps are normally rear-mounted.

The test pump had a maximum output of 15.5 bar. This means the 6.15 bar required to pump the slurry 1600m to the dribble bar resulted in the tractor only doing roughly 1400 rpm (and it doesn't require a tractor the size of the 7530 to run it either).

It also features a hydraulic primer. This works by first starting the pump at idle, pulling the hydraulic lever and waiting until the pipes start to expand (which indicates the pump is sucking). Next shut off the primer, increase the revs and you are good to go.

Ideally after the pumping has finished air generated by a compressor blows out the pipes so that the pipes are cleaned. It's important to keep the pipes clean because it adds a considerable amount of weight to the reeler, and the pipes will last longer if any remaining fluid is blown out.

Slurryquip has started using the remote control system (note the aerial is on the pump), which in conjunction with the throttle robot allows the person in the spreading tractor to shut the tractor revs right down and open or close the diverter gate.

Hoses and reelers

For the dribble bar/John Deere 7930 set-up, a front-mounted system usually holds 600m of the 6 inch pipe while the rear unit carries another 400m of 6 inch and the 600m of 5 inch drag hose.

In the field, the pipe is run out diagonally across the field, and then the reelers are dropped off on the headlands. To retrieve the pipes, hydraulic motors on each side of the reelers provide power to haul them aboard.

One clever design aspect of the Slurryquip system is that both the front and rear reelers are interchangeable. Even more versatile than this is the fact that without dividers on the reeler, any sized pipe or combination of pipes can be rolled up, which also speeds up the shifting process.

The test machine was fitted with heavy duty polyurethane pipe primarily for its durability, although the pipe is not cheap: the 5 inch is $47/m and the 6 inch $52/m, so the 1000m of 6 inch and 600m of 5 inch pipe on this machine makes up for over $80,000 of the total purchase price.

So the costly pipe isn't damaged when on the reeler, Storz couplings are recommended. These are much smoother both inside and out, are the same at each end which improves system versatility, and take up considerably less room than your traditional 'cam-lock' fittings.

The hoses are naturally going to wear out over time; expect five to seven years life out of the drag hose and 10 years from the delivery hose (obviously dependent on treatment). But if they do spring a leak, all the pipes have four collars (short lengths of pipe) on them which can slide along to cover a hole.

Dribble bar

So why chose a dribble bar over your traditional splash plate? Firstly the nitrogen losses are less than 20 percent, rather than nearer to 80 percent with the splash plate. Secondly a dribble bar allows your tractor to stay clean and also significantly reduces the release of smelly ammonia gases.

One of the tricks for young players when working with umbilical systems is to have too little in the way of drag hoses behind the bar. This results in the pipe being pulled in an arc, which makes it want to roll along – twisting the pipe to such a degree that it will eventually stop flow to the dribble bar.

When the dribble bar is working, headland turns are made with the slurry still flowing. The inside of the turn receives more than planned and the outside slightly less, although this can't be helped.

Another key feature of the Slurryquip dribble bar is the hose swivel under the dribble bar as close to the tractor as possible, so not hauling heavy pipe and scuffing at the headland which considerably reduces the pulling power needed to haul the machine up and down the paddock.

Slurry is pumped from the swivel up through a Krohne flow meter to the Vogelsang exactor macerator/distributor and is released from pipes spaced at about 30cm intervals across the 9.5m working width. The in-cab monitor gives the operator a live application rate, as well as a cumulative total.

There's also a machine total which can't be deleted and is essentially the same as a baler monitor.

Output and outlay

Eddie has only had the machine for a couple of weeks so the output variances are not a rock solid indication, but 220m3 per hour is good going and down to 170m3 in heavier slurry or smaller paddocks is also positive.

If you compared this to the output of an equivalently priced 14,000L tanker with a dribble bar, you can move 3.5 to 4.5 times the amount of effluent per hour (assuming a 1km cart, four minute fill, eight minute travel time to and from the paddock and four minutes to unload).

The key to high output is the size of the hose you opt for; big is good. The larger pipe diameter means the same slurry can be delivered as through a smaller pipe, but with much less pressure required.

Verdict

There is no denying this concept has merit. With the interchangeable un-divided reelers, the hose size and swivel action underneath the dribble bar which makes headland turns much easier, this particular arrangement shows a complete concept understanding that speaks of industry experience.

This is a near top-spec machine but there are more basic machines also available, which can provide a cost-effective solution for farmers or smaller contractors.

The beauty of the reviewed set up though, is that if you need to do more area you simply buy more pipe. That's sure to keep the regional council happy and with the gate ways, paddocks and lanes not being compacted, the farmer is sure to be happy too. It's a win-win.

For the latest reviews of farm machinery, subscribe to Farm Trader magazine here.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpg)

.jpg)

.jpg)

.jpg)