Mzuri Pro-Til 4T strip tillage drill test

|

|

|

|

|

|

|

|

|

|

|

Brent Lilley headed south to EuroAgri to check out its latest import: the Mzuri Pro-Til 4T Strip Tillage drill.

Crop establishment practices include anything from full conventional cultivation to create a seed bed through to direct drilling to minimise costs, with minimum tillage systems sitting somewhere in between. While all have their own advantages and disadvantages, determining which is best really comes down to your individual situation.

The somewhat newer practise of ‘strip tillage’ gives farmers the opportunity to lower costs while maintaining and improving yields. This practice basically involves working up a narrow strip of soil for planting.

Having seen strip tillage systems overseas and also in the Waikato to plant maize, I was immediately interested when I heard that EuroAgri had begun importing a Strip Tillage drill that they were running a series of demonstrations on in the South Island. I eagerly set off to Ashburton to check one out.

The drill itself is a Mzuri Pro-Til 4T, which is a four-metre trailing drill designed by UK farmer Martin Lole. Lole himself had been looking for an effective way to establish crops on predominantly heavy clays while also improving the structure of the soil. With a background in engineering, he decided to improve some of the pitfalls he found with other machines and built himself a dedicated Strip Tillage drill. To this day, all design and assembly is still carried out by the company in-house, with fabricated parts outsourced to local suppliers where possible.

The test

On the day of my test, the Mzuri Pro-Til 4T was drilling marrow fat peas at 380kg/hectare into wheat stubble that had been left fallow over the winter. The idea behind this drill is to incorporate the benefits of drilling straight into stubble, such as lower establishment costs per hectare, and improving the soil structure with the benefits of conventional cultivation such as faster germination and early growth.

My test drill was being pulled by a Case Magnum 310 which at 310hp is a fairly big donkey and was pulling the drill at around 10 to 12km/hr. Manufacturers recommend at least 240hp which suggests that’s all that is needed with the front legs on the drill in the ground.

Leading tines

While it may look like a somewhat complicated machine when broken down into sections, it is actually fairly simple. First up, at the front of the drill there are 11 heavy-duty tines with a 363mm spacing between them that are staggered in two rows across the width of the machine. They are much like a sub soiler tine and in front of each one a notch disc leads the way to cut through trash and prevent blockages. The tines are raked to the back of the machine to reduce the amount of clumps and clods that are brought to the surface. The tines are hydraulically adjustable with simple flip over ram shims to set the depth down to a maximum of 250mm.

Packer wheels

Following behind the tines are cleated tyres which are also staggered in two rows. These help to break up any clods while levelling and firming the loosened soil in preparation for planting. Scrapers will prevent them becoming clogged in less than ideal conditions. Hydraulic rams are used to lift the machine up out of work on these wheels for headland turns and transport, as they are set near the midpoint of the machine and spread across its width.

Coulters

Moving back to the business end of the drill, you’ll find the somewhat unique arms that carry the tine coulters. The key to the success of the machines ability to drill into long stubble and trash is thanks these long out-stretched linkage arms and their high mounting point on the frame. Cleverly, each one incorporates a pivot point into the design at the mounting point that articulates each individual coulter allowing it to move side-to-side and freely follow the tilled strip while also minimising the stress on the frame when turning corners on the headlands.

The coulters themselves are also fairly unique, a harden tip penetrates the ground and the seed is split and sown out wings on either side giving you a pair rows 150mm apart in each strip that has been tilled which then leaves around 200mm of untilled ground between each pair of rows. Wide press wheels follow behind the coulters to consolidate the soil and ensure good seed to soil contact to promote germination.

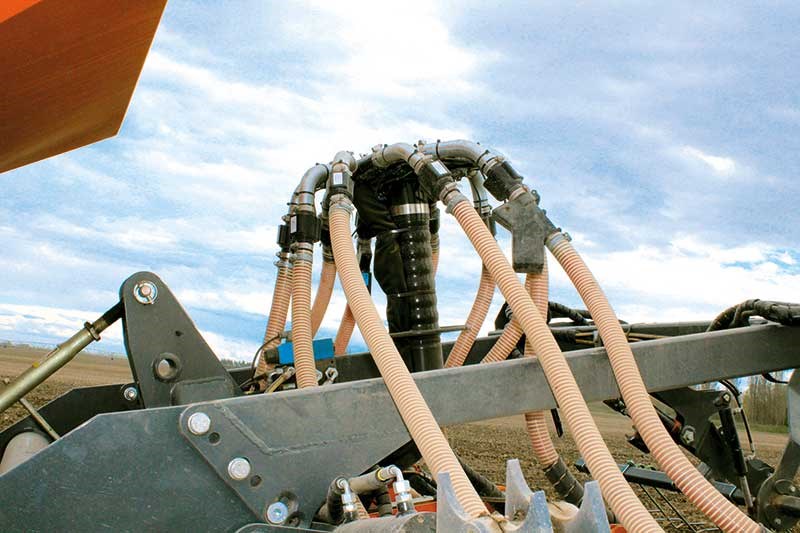

Hopper

The hopper is mounted centrally on the drill for even weight distribution and its tapered design gives the operator reasonable visibility over the drill. It has a capacity of 3400 litres and is split 40/60 if fertiliser is drilled with the front legs. Cleverly, if you’re not using the front section for fertiliser, a plate can be removed which allows the entire capacity to be used for seed. A seed level sensor lets the operator know via the monitor how much seed is in the bin and a sealed steel hatch on top keeps moisture out and provides ample access for filling.

Controls

Up in the cab, the drill is controlled with an RDS monitor which is becoming fairly common place in many drills and is incredibly easy to use. The black and white display shows all the important information such as the fan speed, sowing rate, area covered and forward speed. Buttons down the side of the screen are used to access page style menus, calibration and previously stored info as well as factory settings.

The verdict

When you purchase this drill, you’re not just buying a Mzuri Pro-Til 4T, you are buying into the strip till concept of lowering inputs and improving soil structure while maintaining yields which is a fairly good reason to be interested in this drill.

The fact that it is as well-built (if not better) than other standard drills and packs in as much technology as any other – plus has the ability to drill conventionally cultivated ground – makes this a very appealing option for many in the market for a drill. The only negative I could really see with this machine is the high horsepower requirement.

Pros

- Can be used for single pass Strip Till drilling or on cultivated ground

- Ability to loosen sub soil without bringing clods to the surface

- Incredibly well-built with impressive attention to detail

- Coulter design allows drilling heavy stubble and trash

- Pivot point built into each coulter arm

- Electronic drive with radar for ground speed

- Seed flow meters to alert the operator for blockages

Cons

- High horsepower requirement

- Five sets of remotes required

Read the full article in the latest issue (#227) of Farm Trader magazine. Subscribe here.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook