4AG Titan Roller Drill review

|

|

|

Check out this review of the 4AG Titan roller drill…

Wayne and Jacqui Anderson have been contracting under the W & J Anderson brand for 14 years, covering the region between Porangahau and Waipawa in Hawke’s Bay, from the Ruahine Ranges to the sea, and keeping out of trouble by also running 400 bulls on their beef farm.

Their fleet comprises of three modern John Deere tractors with two new 7230R machines, which have the E23 transmission, and one 7430.

Because the company’s small but dedicated team only does ag work, they usually wrap up the spring work before Christmas, allowing them some time to enjoy the summer months on the water with family and friends – something silage contractors are no doubt a little envious of. Although when it’s busy, the Andersons run 12-hour shifts.

Their new Titan 6300 ‘Profi’ roller drill, with output in excess of five hectares per hour, leaves the old three-metre machine for dead. Wayne loves the 6.3 metre width, and comments ‘Our clients are rapt with the seeding job it does’.

Having upgraded from their old three-metre roll – seed – roll combination, stability on the hills and the increased working width were two features at the top of the list for the small but dedicated team. And once you start looking, there are many features which really do make this machine stand out above others on the market.

Machine features

- Brakes (optional)

- Mudguards

- Hydraulic parking jack

- 800-litre hopper (320kg grass seed) with patented self-levelling mounting

- Hydraulic accumulators give even weight distribution and contour following of gangs

- Highly accurate sowing. Different capacity seed rollers to cater for wide variety of seed type and rate

- Hydraulically driven fan for optimum airflow to 16 seed hoses direct from hopper. Smooth hose routing and no Y-junctions to distribute even, accurate seeding across full width

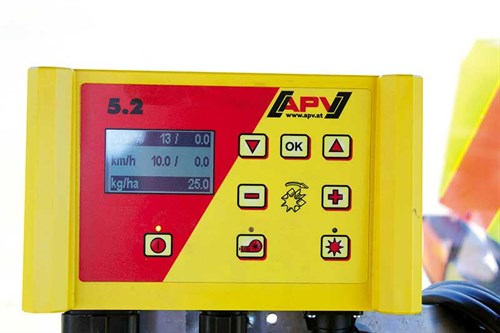

- Radar ground metering for accurate, hassle-free speed calibration. No drive wheel to maintain, or become fouled or damaged

- Platform for loading seed into the hopper is a very safe and large area with ladder

- You can have the choice of levelling paddles or chain cover harrow

- The TitanLoc axle security nut system on each gang

- Gang bearings are encased in rubber and don’t require greasing

- The weight of the machine gives good consolidation for seed to soil contact, with large 550/575mm diameter Cambridge and breaker rings

Now I like the steep stuff every now and then as it keeps you on your toes, but not day and night every day! Because of the very steep going, often putting your feet on the front or side windows is not out of the question. While the large working area of the machine, as well as its surefootedness, does ensure accurate seeding, the new machine hangs tight on steep sidelines, and does not slide down the hill and come along beside the driver’s door to meet them like the old roller combo.

It is not just the steep paddocks that can provide the headache as many will know getting to steep paddocks often requires going up narrow gravel and dirt tracks which are only usually as wide as the machine so the narrow transport width comes in very handy.

A large portion of the Anderson’s extra workload is from the sheep and beef guys having a couple of great years, although having said that, they deserve it as they have had plenty of average ones in the past. On top of this a lot of customers are second- and third-generation who are using the significant increases and science for animal genetics as well as grass hybrids, which have significantly improved the performance on this type of country, and as a result the accuracy of the air seeder and the stability of the roller fits perfectly into this system.

Luckily the dairy doldrums that has affected most of the country hasn’t affected the Anderson’s workload as most development work has been put on hold.

The success of this machine is largely to do with the excellent build quality but also 4AG’s willingness to listen to its customers and use itself as the vehicle between the ideas of the guys who spend hours going around paddocks and the factory where they have the tools and the design know-how to make it happen. This is their way of getting "Kiwi DNA combined with European build quality".

I have mentioned a list of machine features above (and trust me there are many) but there are a couple I would like to expand further as these are the ‘key’ reasons this roller works so well.

The first is what they have dubbed the ‘TitanLoc’ which is a clever play on words as this TightenLock is exactly what it sounds like and significantly increases the life expectancy of the most expensive wearing part on the machine – the rings. This is a 90mm hex nut which can be tightened (with the large spanner stored on the machine) to remove any play in the rings which adds strength and protection to the axle shaft and particularly in stony conditions will prove a very handy tool.

Speaking of keeping rings tight, this is even more important with the large heavy rings fitted to the Titan series rollers. The ‘DuraForge’ roller ring is ideal for working stony virgin ground, Canterbury type soil or ex forestry blocks which can be all in a day’s work for Kiwi contractors. The GGG50 ductile iron (cast steel) rings have high impact resistance and come with a five-year manufacturer’s warranty, which will give you a good dose of peace of mind.

These rings are not built strong from fancy light weight material either these things are heavy, the machine weighs five tonnes empty but the team at 4AG along with the factory quickly discovered there is no point having the heaviest roller if that extra weight wasn’t distributed evenly across its full working width. This brings me to my next key feature – the clever float system – which allows all the wings to be mounted (where the strength is) from the chassis of the machine and large hydraulic accumulators to take care of the contour following of the wings, and weight transfer.

The verdict

This machine, like most European-manufactured gear, is built to a very high standard. What I like about these particular roller/drill combination machines is the extensive input by Kiwi farmers and contractors – good honest ideas that have made this machine ideal for New Zealand conditions. Considering this, combined with the build quality, weight and clever features it already came jam-packed with, it’s hard to see why you wouldn’t want to have a gander at it.

Pros

- Heavy ductile iron rings

- TitanLoc means the rings are always tight for reduced wear

- Large hopper capacity

- Radar ground speed and metering for greater accuracy

- Much lower seed needed than the large amount to simple spread across the box on normal roller drills

- Large and safe seed loading area

- Even weight distribution which still has all the strength at the main wing pivot

- Rubber encased gang bearings which are completely grease free

- Front levelling paddles or cover chain harrow option increase the versatility of the machine

- Large transport wheels and narrow transport width make it ideal for road transport as well as navigating around tricky off road tracks

Cons

- The low profile tyres need to be heavily inflated to carry the weight of the machine and as a result it does bounce on the road, particularly metal roads

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook