Taege M3 Metering Series Review

|

|

|

|

|

|

|

|

|

|

We put Taege’s M3 Metering Series to the test in this cover story from the August issue of Farm Trader magazine…

When it comes to establishing pasture on cultivated ground, a roller drill tends be the favourite of many due to its lower costs, broad coverage and very shallow seed placement which sees excellent results. With that in mind, it’s great to see a New Zealand-owned company, Taege Engineering, continuing to provide innovative solutions for farmers and build a roller drill (M3 metering series) which combines many of its proven designs.

Construction

What I particularly like about this machine is that while it is a relatively new concept from Taege, it is built using a combination of its tried and tested components – all of which are held together on a sturdy single piece drawbar beam running the length of the machine. As with other Taege machines, everything is well engineered with a tidy finish and most of the steel work is galvanised for longevity.

At the rear, steps and platform give safe easy access when loading seed into the hopper and both the hopper and the tynes are also mounted directly to the draw beam. At the front is a sturdy towing eye, although to get the most out of the contour following ability of the tynes and the tyres, the main beam needs to be run level, so the machine is ideally used on a quick hitch on the three-point linkage. A screw jack on the front makes unhitching simple and straightforward.

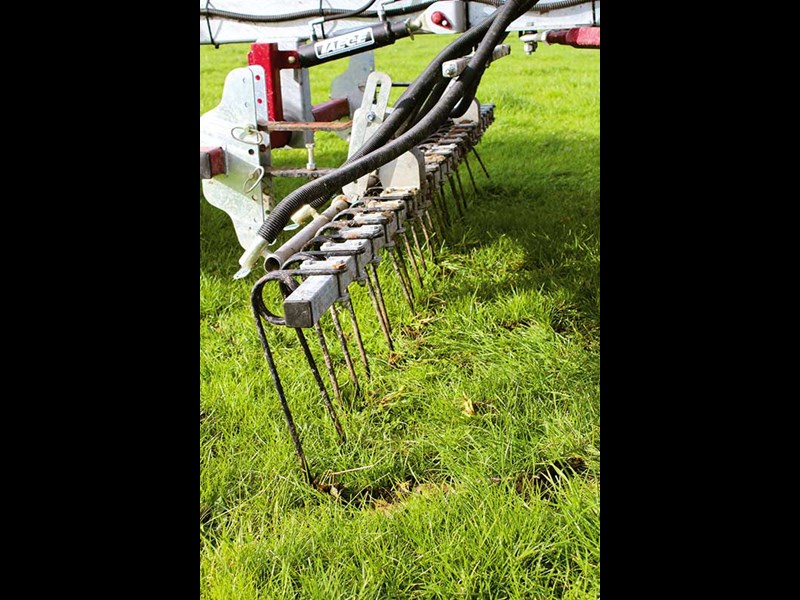

Tynes

Up the front of the machine is a row of leading tynes, which are set up so they can conveniently be hydraulically lifted out of work from the cab. As the design incorporates a parallel linkage that they are mounted on, the tynes will float up and down following the contour of the ground within reason.

This linkage also ensures that as they move up and down, the angle of the tyne in relation to the ground remains the same. Optionally the machine can be supplied with a choice of two different tyne bars – an angled covering tyne which lays flat on the ground, or a straight more aggressive tyne which produces more drag like a rake through the soil.

The tyne bars are mounted on heavy-duty pins on the end of each parallel linkage so they can easily be changed in minutes by removing the lynch pins and sliding them out from under the machine. Also taking advantage of the parallel linkage is a seed bar with deflector plates to spread the seed (which is mounted off the tyne bar on an adjustable slide, so the height relative to the tynes can be set).

As the tynes follow ground contour, the seed is always applied from the same height above the ground to ensure an accurate and even spread.

Roller

The tyres are arranged in two rows, on five oscillating bogie axles across the width of a three-metre machine, with two tyres at the front and two at the rear. This allows the tyres to move in pairs independently giving a degree of contour following to ensure they are in contact with the ground at all times. It also prevents a bow wave of soil forming in front of the roller and leaves an impressively smooth finish.

Metering series and hopper

Mounted on top of the main beam is a Taege mini hopper. This is a multi-fit unit which the company builds and fits across a range of its machines for accurately applying seed. It uses a 250-litre plastic moulded hopper with a sealed screw top lid to keep moisture out and, as the plastic is somewhat transparent, you can see the seed level in the hopper from the cab.

To meter the seed out, double sponge rollers are used. This has long been a point of difference on Taege drills. The Taege team firmly believe in the benefits this offers over conventional plastic metering wheels, including the ability to handle almost all seed types and sowing rates, without damaging the seed.

As the seed is dropped from the metering unit, a 12-volt two-speed electronic fan is used to blow seed out through the eight hoses which are spaced across the width of the machine. It is then spread with deflector plates on the end of each hose to give even coverage over the three-metre width.

Control and calibration

Like almost all drills these days, the metering unit is electronically driven and the ground speed is measured off a small wheel which runs on top of one of the roller wheels for a simple self-contained unit.

While the control box for the unit in the cab is a little basic with a relatively small screen, it is very user friendly with large clearly labelled buttons on a membrane panel. The target seed rate is easily set and can be changed on the move with a plus or minus button. Measured ground speed is also shown on the screen, along with the area covered.

As you would expect there is the ability to save job sizes, and calibration rates for different crops can also be named and saved for easy recall at a later date. This is the same control box found on all Taege drills, so anyone who has previously operated a Taege drill will be right at home. This also means the metering system and mini hopper can be controlled with an existing monitor if, for example, it is fitted to the back of a drill.

The verdict

Since being purchased around a year ago by an agricultural contractor, this Taege M3 metering series roller drill has been used to sow a variety of crops in different conditions, all with pleasing results including summer crops sown in the spring such as turnips, millet and pasja, as well as grass sown in the autumn – all on cultivated ground.

Overall, the Taege M3 metering series roller drill is very well built, easy to operate and has proven very adaptable to a wide range of applications, making it a handy machine to have around.

Pros

- Unique tyre roller design for improved results.

- Contour following tyres and tynes.

- Hydraulic control of the leading tynes.

- Simple double sponge roller metering can handle almost all seeds and rates.

- Accurate electronic metering and control box with simple calibration.

- Air assisted seed delivery for accuracy even on hills.

- Options for easily changed leading tynes to suit the conditions.

Cons

- A three-point linkage quick hitch is required to run the machine at its optimum.

- Small screen size on control monitor.

Read the full review in issue #234 of Farm Trader magazine, which is on sale now!

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook