CFMoto trip to China

UTVs being assembled in the overhead production line.

UTVs being assembled in the overhead production line.

Quality assurance checks are performed during and after the assembly process.

Quality assurance checks are performed during and after the assembly process.

CForce 550cc quads assembled and lined up ready for shipping.

CForce 550cc quads assembled and lined up ready for shipping.

The Chinese police force get to ride around in these smart-looking machines.

The Chinese police force get to ride around in these smart-looking machines.

|

|

UTVs being assembled in the overhead production line.

|

|

|

|

Quality assurance checks are performed during and after the assembly process.

|

|

|

CForce 550cc quads assembled and lined up ready for shipping.

|

|

|

The Chinese police force get to ride around in these smart-looking machines.

|

|

|

|

|

|

|

Brent Lilley was invited to tag along on the inaugural CFMoto trip to China with a group of dealers from around New Zealand.

The trip was the chance for a first-hand look at CFMoto's impressive factory and headquarters in Hangzhou, where its machines are built. Ten of us assembled in Auckland for the flight to Shanghai; the start of an amazing and whirlwind four days in China.

The first stop was Shanghai. Its impressive wealth is showcased on the streets with Ferraris and Lamborghinis being common sights. In contrast, those same streets are shared with people pushing handcarts and trying to survive on little money.

The following day we travelled three hours out to Hangzhou, where the CFMoto headquarters and factory are based.

The CFMoto factory

On the third day it was time to get down to business at the CFMoto factory and headquarters, which is spread over 15 hectares.

This encompasses the head offices, engine and vehicle factories, research and development departments, cafeterias and several apartment blocks to house its workers, along with a short section of test track where we got to try out the latest machines later in the day.

Around 1300 people are employed to produce 300,000 engines and 200,000 power sports vehicles which are now exported to over 60 countries around the globe.

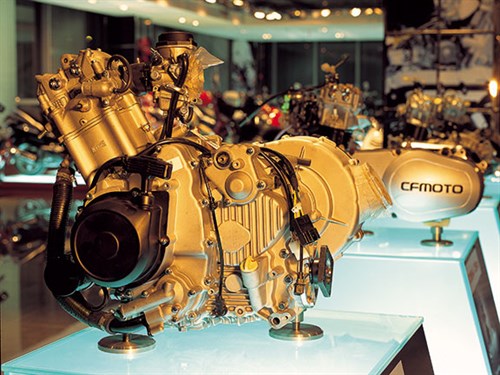

Engines

CFMoto has now been building engines for around 20 years. In my opinion, they have definitely got this part right. It is the key to the success of their machines. They control the design and construction right from the very start with their own aluminium foundry (at a different site) which casts the engine housings.

Our tour started with dozens of robotic CNC laser machines. These take care of precision cutting and tooling on the engine components. Although hand-loaded by factory staff, they are computer programmed and controlled to give the precise tolerances required in a finely tuned engine.

Further through the factory are two engine assembly lines where the in-house components are combined with reliable outsourced parts such as injectors and throttle bodies from reputable Bosch and Delphi suppliers. This workforce of precision engineers operates in a spotless, dust-free environment.

Every single engine built is run and tested before it leaves this area of the factory; underperforming engines are re-tuned, or stripped and reassembled at the slightest hint of any problem, with a zero tolerance policy for defects ensuring engines are of the highest quality.

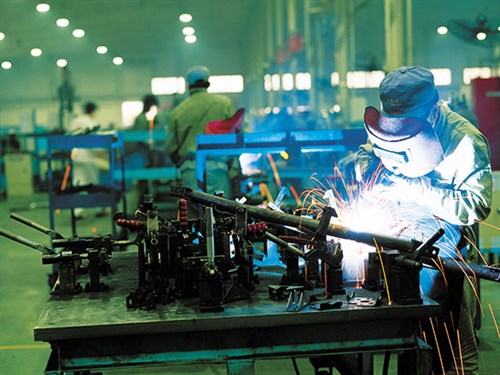

Construction and assembly

Across at the vehicle construction and assembly side of the plant is the frame production area. The company has invested a serious amount of capital into five robotic welding units that are used to build frames for all the machines.

The robotic arm welders are positioned to work on a large vertical table, with a jig on each side. Required materials are loaded and clamped in the correct positions by workers, while the robot is busy welding on the other side. When it finishes, the table is rotated and the welding continues on the next frame.

In the meantime, the worker unloads the completed frame and reloads the jig for the next one. This system has an incredibly high output, but more importantly, maintains consistent quality, as a robot can make the same perfect weld all day every day.

A paint shop in the factory takes care of prepping and painting all components to a high standard. The plastic body work on most machines is outsourced to a nearby plastics manufacturer and specified colours are injected during the moulding process.

All the components are finally brought together in a huge main assembly hall. With five separate moving assembly lines allowing five separate models to be in production at one time, it's an impressive sight. Work starts at one end, from the ground up with just the frame, and a fully built functional bike can be driven off the other end.

Assembly is a hands-on process for the many factory workers, with quality assurance checks throughout the process once again demonstrating the company's dedication to providing a quality product. Once off the assembly line, machines are disassembled where required, and packed into crate for shipping.

The verdict

I am fortunate to have been through some fairly big-named factories throughout Europe, all producing machinery for the agricultural sector. There is no doubt they are impressive. What I'm pleased to be able to say is that the CFMoto plant operates at an equally high standard and would match most in Europe.

It is exciting to be involved with something from the start and that is the unique opportunity here. Like many, I admit that I was initially somewhat sceptical of CFMoto machines. There are a massive amount of products coming out of China, and some are of appalling quality.

After my visit to China and the chance to see the factory in person, and speak to key people involved, I'm willing to put my reputation on the line and say that I'm confident the popularity of CFMoto products will only grow in New Zealand, and it will almost certainly become a major player in the market over coming years. I hope to be able to say that I wrote it here first.

Mojo Motorcycles

Mojo Motorcycles Ltd is now the sole importer for CFMoto machines into New Zealand and Australia. It was established in 2003 in by Joshua Carter and Micheal Poynton, who joined us in China for the factory tour.

The company also distributes Sherco TGB and Daelim motorbikes and is one of the fastest growing motorcycle companies in Australia, with retail sale of around 5000 units per year through a network of around 80 dealers.

For the latest farming news and reviews, subscribe to Farm Trader magazine here.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook