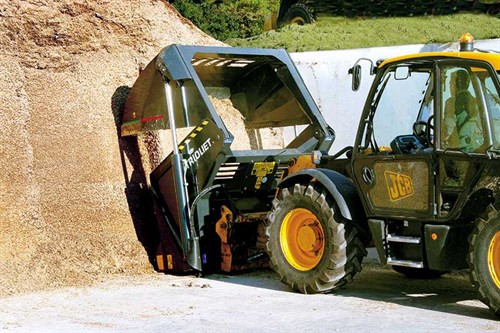

New release: Triomaster S silage cutter

The European-designed and manufactured Triomaster S silage cutter is set to arrive in New Zealand in time for this summer’s silage season

The use of a silage cutter helps maintain silage quality and consistency according to Claas Harvest Centre Triolet product manager Blair McAlwee.

"If you go to all the trouble of producing top-quality silage, then it makes sense to use the best technology to feed it out and get the best results," he says.

"Silage needs to be removed as carefully as possible to prevent air from penetrating the stack, particularly if there is poor compaction."

The Triomaster S is a purpose-designed silage-cutting implement that effortlessly removes up to 45cm of silage from the face of the silage pit. Unlike conventional silage ‘grabs’ or buckets, which pull the silage from the face, the Triomaster S has a fixed blade that shears through silage without affecting the structure of the wall or the stack.

"There’s no lifting, pulling, vibration, or compression associated with conventional types of machinery, which helps to maintain consistent silage quality and consistency."

Available in volumes of two and three cubic metres, the Triomaster S can be fitted to any telehandler or front loader with a lift capacity of more than 3.5 tonnes.

It can be fitted to most loader linkages, including the Euro Hitch, Quick Hitch, or JCB Q-Fit mounting systems.

"The fixed knife is in the optimum radial position throughout the cutting curve, which means little effort is required in terms of hydraulic capacity. This minimises the weight of the cutter and maximises its loading capacity."

Triomaster S Features

Triomaster S comprises a sturdy U-shaped frame, a closed bucket, two hydraulic cylinders, and exchangeable, hardened stainless steel knives.

"The closed frame prevents spillage in the yard on the way to the mixer," Blair says. "Once you’re there, the curved bottom plate means the bucket only has to be tilted slightly to empty."

Electric monitoring protects the system from excessive use or unexpected situations.

An optional weighing system allows the operator to measure loads directly at the

pit, avoiding additional transport time or inaccurate loading.

Triomaster S can also be used to effortlessly cut round bales – lengthwise or crosswise – or to handle loose products.

Blair recommends that producers remove about one metre across the entire face of the silage pit each week during winter and two metres a week during summer.

"The goal is to refresh the silage wall frequently to minimise the time between when the silage is exposed to air to when the cows actually eat it," he says.

"Once the pit is exposed to air, the yeasts start to ferment valuable nutrients into heat. Yeasts and moulds growing on deteriorating silage may also contain toxins. Silage with a high dry matter content is particularly prone to deteriorating when exposed to air or warm temperatures, which means silage fed over summer typically has higher losses."

About Trioliet

Established in the Netherlands in 1950, Trioliet is a world leader in livestock feeding technology, including mixer feeder wagons, silage cutters, diet feeders, and automatic feeding systems. Troilet has been available through the Claas Harvest Centre network since 2007.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook