Event Preview: EuroTier 2021

Check out the latest award-winning innovations from around the globe, featuring as part of the upcoming EuroTier 2021 virtual online show

Held biennially in Germany, the 2021 EuroTier event won’t be attracting its usual crowds and buzz – at least not in person. The prestigious animal husbandry show was due to take place in November last year and was postponed until this month in the hopes that lockdowns and public gathering restrictions would be at an end.

However, it was not to be, and the show is now being run as a virtual event from 9 to 12 February, hosted by organisers DLG.

One thing that won’t be diluted is the importance and relevance of the EuroTier traditional innovation awards announced recently at a virtual preview event, which Chris McCullough reports on over the following pages.

In total, DLG made eight awards, including one gold medal and seven silver medals from a total of 80 innovation entries.

Winning a medal is regarded as a significant honour, and the latest recipients included methods of reducing livestock emissions and systems to take the strain out of sorting eggs.

Gold medal for cow toilet innovation

It’s not your everyday invention but a cow toilet (developed by Dutch company Hanskamp AgroTech BV) was awarded the only Gold Medal for innovation at the EuroTier preview event.

Eurotier is the world’s largest animal husbandry show and is held every two years in Germany (organised by the German Agricultural Society DLG).

Although the show that was scheduled to take place last November didn’t happen due to COVID-19 restrictions, a recent virtual show preview saw the prestigious innovation award winners announced.

During the virtual event, DLG presented a single gold medal (to the cow toilet), along with seven silver medals to products from a list of 80 entries.

The Dutch are renowned for inventing somewhat wacky equipment for livestock, but this latest toilet creation has left farmers feeling a little bit ‘flushed.’

The company behind the concept Hanskamp, took to gold medal for developed a cow toilet that collects urine in an effort to reduce ammonia. The design also includes a feed station.

Designed primarily to ease the ever-increasing regulations on the dairy industry, the CowToilet is an automatic urinal that cows use voluntarily and is designed to collect urine before it hits the floor.

Approximately 90% of ammonia emissions come from agriculture according to Wageningen University and Research (WUR) in The Netherlands.

Excess ammonia emissions are a big deal in Europe and there are national limits in force aimed to reduce gases.

When manure and urine mix, ammonia is formed. If this is released into the air, it can precipitate in nature, causing large amounts of nitrogen to end up on the ground.

Plants can only process up to a certain amount of nitrogen and the remaining amount acidifies the soil and affects the groundwater. High concentrations of ammonia are harmful to humans and animals.

In an effort to limit ammonia emissions from the agricultural sector, dairy farmers have to pay high fees to meet ammonia emission and manure disposal requirements.

Cows produce 15 to 20 litres of urine per day and have a natural nerve reflex just above the udder that when rubbed causes them to immediately urinate. Hanskamp developed the new CowToilet to automate this long-known technique to make a cow urinate just after it has finished feeding.

The CowToilet is placed against the cow’s suspensory ligament and moves in unison with the cow. The technique locates the nerve, and once located, the nerve, which triggers the urinary reflex, is stimulated and the cow starts urinating.

The urine is collected in the CowToilet container and extracted through a suction line into a separate storage tank.

Cows go to and use the CowToilet voluntarily because each visit to the toilet is combined with the animals receiving their daily portion of feed.

As most of the urine is collected, this results in a significant reduction in ammonia emissions, which is good for both the environment and animal welfare as well as providing a healthier climate in the shed.

The CowToilet also offers economic advantages, as it saves on manure storage costs and may even be an alternative to ammonia emission-reducing floors.

As a welcome sideline, using the CowToilet may even provide some income as pure urine can be used as a high-quality raw material in, for example, precision fertilisation.

There are also ongoing developments in which urine is used to generate ‘yellow’ power or as a source of hydrogen. The unit is set to be available on the Dutch market later this year and is currently being tested on several farms in the Netherlands and at Wageningen University.

A CowToilet has recently been installed at the well-known German testing facility Haus Düsse in Bad Sassendorf for research and training purposes.

Calf monitoring technology wins EuroTier animal welfare award

New sensor technology that can detect diseases in calves has won the Animal Welfare Award at the virtual Eurotier preview show.

As part of the EuroTier innovation awards, products that foster the exercise of species-specific behaviour patterns and positively support animal health are additionally presented with the Animal Welfare Award by show organisers DLG together with the German Association of Practising Veterinary Surgeons.

Technical solutions that lead to increased animal welfare and animal health are therefore specifically highlighted.

This time around, the Animal Welfare Award 2021 is being presented to Futuro Farming GmbH, Regensburg, for its Calf Monitoring System.

By means of continuous calf monitoring and speedy feedback to the farmer, the system enables effective health monitoring for each individual calf in the population.

The early warning system for calf diseases detects outbreaks of disease up to three days in advance and can be used from day one for calves kept individually.

A sensor is attached to each calf igloo/box for individual housing, which records the behaviour of the calves. The sensor system sends this data to the servers, where an algorithm evaluates the calves’ data and identifies calves that are susceptible to disease.

These abnormalities are sent to the farmer’s smartphone via app who then receives real-time notifications so that they can treat calves as early as possible.

The system for the early detection of diseases in calves is based on a precise, energy-saving, and, above all, non-invasive infrared sensor, which detects the calf’s behavioural pattern.

The sensor data are promptly evaluated with AI and a prognosis for potentially developing diseases is produced. The information from the evaluation is made available to the farmer directly via an app and an online platform.

Thanks to earlier treatment, the continuous monitoring of the calf and the quick provision of information to the farmer can help to make the courses of diseases milder and reduce calf mortality.

By quickly treating a calf, particularly during the first few days of its life, the monitoring system can contribute directly to protecting the calf and its health and is, therefore, able to significantly improve animal welfare.

This innovation also won a silver medal at the event.

Seleggt Acus sampling system proves medal-winning

Egg-laying chicken genotypes are considered unsuitable for producing poultry meat due to lower product quality and cost-effectiveness. For this reason, the male chicks of these breeds are generally not reared.

However, as the culling of day-old male chicks has become a societal and political issue, with a ban on this practice being considered, the industry is seeking alternatives to this process.

One such alternative is in-ovo sex determination with hormone analysis on the eighth or ninth day of incubation, which is currently being the most extensively developed and commercially useable method.

The Seleggt Acus sampling system, developed by respeggt GmbH for this purpose, is already in practical use. Sampling the test fluid from the allantois using a needle, this system is only partially automated.

The risk of injuring the allantoic membrane exists, which can lead to a reduction in the hatching rate. The hourly capacity of a single sampling unit for this system is around 600 eggs. The innovative Seleggt Circulus system is a significant leap forward compared to the predecessor system. Operating fully automatically, the allantoic fluid samples are generated in a non-invasive way.

Cleaning the sampling needles is, therefore, no longer necessary and the sampling time has been reduced to just one second per egg. In three-shift operation with 20 hours of operation per day, one Seleggt Circulus sampling unit, therefore, has a weekly capacity of 360,000 hatching eggs, corresponding to 150,000 to 180,000 laying chicks, a significant increase in performance in comparison with the predecessor system.

Non-invasive sampling and the vastly increased hourly capacity have established the prerequisites for universally replacing the previous culling of male chicks in hatcheries with in-ovo sex determination.

Silver medal award for new manure system

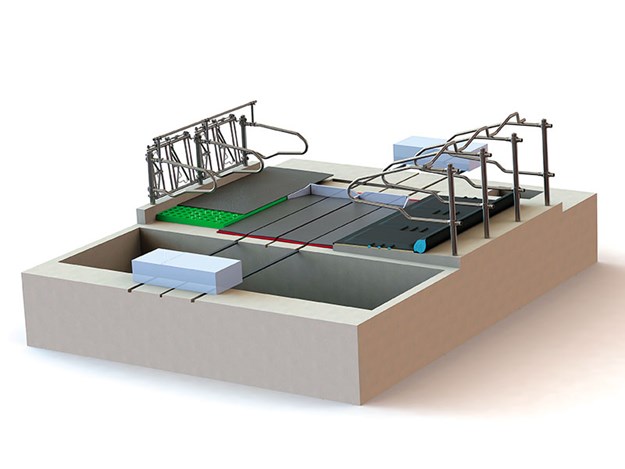

French company Bioret collected a silver medal for its new Delta X Pack system for collecting manure from livestock sheds.

The formation of ammonia on floors can be reduced through the early separation of faeces and urine. In dairy farming, animal urine is one of the main causes of ammonia emissions, particularly when it remains on the floors and in contact with the air and faeces for long periods of time.

With the Delta X Pack, Bioret has further developed a product that enables faeces and urine on the floors of dairy cattle sheds to be collected automatically, quickly, and easily and then transferred to separate storage areas.

To accomplish this, a contra-rotating conveyor belt system has been integrated into a rubber mat system with a three percent gradient. The belt system diverts the urine collected in the central gutter to the liquid store and the animals’ faeces to the solid material store.

The fast and effective separation of faeces and urine is extremely important not only for keeping the floors clean but also for fostering animal health and improving the indoor animal housing environment.

The company also says the environmental impact may also be reduced as a result.

Siloking introduces straw chopper for SelfLine feed mixers

During the recent virtual preview of EuroTier, Siloking introduced a straw chopper version for some of its feeding mixer wagons.

Livestock farmers recognise the benefits of mixing straw in feed rations either because of its structural effectiveness or because of other fodder shortages.

To avoid selection during feed intake by the cattle, straw must be cut short and mixed well. Long straw can be used in the feed mixer before and during mixing of the actual ration, but this takes some time to be cut properly.

With this in mind, Siloking has introduced a straw chopper version for the SelfLine 300+, 500+, and 1000+ feeder models to ensure fast cutting of larger quantities of straw in the ration.

The family-run company is based in Bavaria, Germany and produces innovative feeding technology distributed to more than 50 countries.

The product range includes trailed, self-propelled, and electrically driven feed mixers from five to 32 cubic metres for livestock farms, stationary mixing, and dosing systems up to 80 cubic metres for feed centres and biogas plants, as well as silage extraction and distribution machines.

The hydraulically driven straw chopper is mounted directly behind the milling head and extends over the full width of the loading chute. In chopping mode, the flow of forage is diverted to the straw chopper by a flap that swivels into the milling channel.

The rapidly rotating chopper blades beat the straw through the counter blades and feed it back, chopped into small pieces, onto the loading conveyor belt, which then transports it into the mixer.

The straw chopper is operated conveniently at the touch of a button from the multifunction armrest in the cab. Mixing in of the precisely cut straw can be better dosed, it considerably reduces fodder losses through selection, saves time during loading, and reduces diesel consumption through shorter mixing times.

The straw chopper is mounted directly behind the milling head and cuts the straw already on its way to the mixing container.

Innovation accolades for egg refilling system

It’s a common and time-consuming factor on egg farms and hatcheries for manually sorting eggs on trays, but technology is on hand to ease that pain.

The hatching eggs from broiler parent livestock farms are delivered to central hatcheries, where they are sorted according to quality and weight before being placed into the incubator.

In addition, eggs that are not positioned with the blunt end pointing upwards in the tray have to be turned. This leads to a high number of incompletely filled trays that have to be manually refilled.

Often, the eggs are also transported on conveyors where they can come into direct contact with one another, possibly resulting in damaged shells.

In the new system presented by Nectra SAS, the eggs are transferred from the delivery trays to egg moving cups that move freely on a transport conveyor. Here, the eggs can be automatically and individually sorted according to quality and weight and can also be turned if they are positioned incorrectly. The freely moving egg cups are backed up for transfer to the hatching trays, unoccupied egg cups are automatically removed and the remaining, filled egg cups are then transferred automatically to the hatching trays so that no gaps occur.

The system significantly reduces the likelihood of damaging the eggshells and automates the hatching tray filling process. This considerably lightens the workload and leads to an improvement in hatching rates in the broiler chick hatcheries.

New teat hygiene system recognised

A new teat disinfection system to boost calf heath won a silver medal for its manufacturer Urban at the EuroTier preview.

Hygiene is critical in all livestock populations, and this is also the case during feeding in calf rearing. The risk of pathogens being passed from calf to calf is particularly present during automatic feeding.

The Alma Pro Hygieneset represents the innovative use of well-proven UV-C irradiation, reducing the microbial load in calf feeding.

Specific UV-C irradiation at relevant hygiene points of the automatic calf feeder is intended to lead to significant improvements in comparison with previous technical concepts for reducing microbes.

Besides the UV-C irradiation of the boiler water, which ensures perfect water quality for mixing the feed from a hygiene perspective, the additional, monitored irradiation of the teat represents a vast improvement.

In short feeding breaks between the individual calves, the teat and the adjacent contact surfaces are irradiated, thus killing a multitude of pathogens during operation.

The risk of microbial transfer by the calves is also reduced, thanks to this microbial reduction and reduced microbe multiplication.

Compared to other sanitisation methods available on the market, Urban’s Alma Pro Hygieneset is a safe, resource-efficient, and chemical-free option for reducing microbes in the calf feeder area.

New sensor keeps eye on correct calf milk mix

A new smart sensor that closely monitors calf milk powder mix won a silver medal at the EuroTier preview show.

Rearing calves on any farm is time-consuming but more so on a dairy farm where automatic calf feeders have proved invaluable and ensure animal-friendly and needs-based calf feeding.

Powdered milk, and also whole milk to a lesser extent, is usually used in the automatic feeders and a combination of both is additionally possible.

Fluctuating dry substance contents in new powdered milk batches necessitate constant checking and adjustment of the automatic feeders’ basic settings to achieve a consistent powdered milk concentration in the feeder milk and optimum feed qualities.

In practice, this important activity is occasionally forgone due to time constraints, as the milk replacer concentration has to be adjusted manually on the automatic feeder after calibration.

However, help is now at hand from Holm & Laue with its Brix-TS Sensor, which is an electronic refractometer sensor that has been integrated into the mixing tank of the ‘Calf Expert’ automatic calf feeder. Here it continuously measures and monitors the dry substance content of the freshly mixed calf milk.

In the event of deviations, the system automatically corrects the concentration in the feeder milk. If whole milk is used, a consistent dry substance concentration can also be ensured in the feeder milk by adding powdered milk if necessary.

Lightweight boom from Moscha receives EuroTier silver medal

A lightweight slurry spreader boom produced by Moscha has been recognised for its innovation with a silver medal at the recent virtual EuroTier preview event.

Nowadays, reducing emissions, particularly when spreading slurry, is an important topic and one that manufacturers are taking seriously.

Spreading liquid manure and fermentation residues close to the ground and with correspondingly low emissions is important due to reasons of environmental and resource protection.

Because of the size and weight of the booms, modern spreader technology all too frequently reaches its physical limits, particularly on hilly or even mountainous terrain in designated grassland regions.

The Moscha Spreader boom with plastic pipe as a supporting construction element is characterised by its simple and, at the same time, extremely lightweight design.

Moscha achieves lighter boom weights by using covered plastic pipes instead of a design exclusively using metal. This development of the product to use alternative materials significantly reduces the weight of the folding boom.

Besides saving both material and fuel, this also extends possible applications of the system because the precise spreading of liquid manure close to the ground with a drag hose or drag shoe attached to corresponding boom technology can also be used on lighter trailers requiring less tractive power and on more extensively contoured terrain.

Find new and used farming machinery on Farm Trader NZ

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.gif)

.jpg)