Kiwi Made: West Ridge

At West Ridge, it’s all about creating premium wool garments from 100% NZ wool

South Island farming couple Murray and Julie Hellewell came up with the enterprising idea to manufacture a range of woollen jerseys made from their own Perendale wool.

They called their business West Ridge after their 640-hectare beef and sheep farm, located near Lawrence, a rural town that was once the centre of New Zealand’s gold rush days.

An inspiration

|

|

The Hellewell family behind the West Ridge business

|

Murray has long been disappointed at how little farmers receive for their wool. In 2019, he was only getting $2.50 per kilo. The latest price he received was $1.10–1.30/kilo. He refused to believe this valuable natural product should go to waste, and so set about doing something to combat these dismal returns.

"I was frustrated at how people were wearing synthetic clothing when we had a great natural product right in front of us. I’ve always worn wool and loved it. It keeps you warm and is breathable."

Murray had always wanted to do something with the end product of the wool he was farming. After talking it over with Julie, they took the plunge (along with John Milne from Ken Milne Wools) to make jerseys commercially using their own fleece.

Starting out

|

|

Seeing their wool put to good use has boosted the Hellewell’s spirits

|

The first West Ridge jerseys were made with simple designs in mind: one had a collar, and one had a hood.

Their first customers were people they knew in the area, and they tried them out themselves as well.

"We wore them heaps and figured out what worked and what didn’t. We are still changing little details on the original ones.

"We made the same jersey design for workers who require tough gear, but reinforced areas to stop them from wearing out so fast. We have another prototype on the go at present – a short-sleeved style. We don’t do any fancy research; we base it on how the garment is worn by like-minded people."

The fleece gets scoured in Canterbury, then spun and dyed in Wellington. The jerseys are knitted in a small factory in Dunedin.

Recalling days past, Murray says, "It’s interesting to note that there’s an old factory in Milton, 40 minutes from us which, in 1945, used to employ 500 people."

Business is flourishing

|

|

Perendale sheep produce excellent wool for knitwear

|

Murray and Julie fit the work for their garment business in and around their farming business.

"Everything is done online through our website, and we often process our orders at night when the kids – Riley, seven, and McKenna, four, are in bed. Julie is flat-out most days sending out orders as well. Before we started this, she used to help me on the farm, so I’ve now lost a labour unit," laughs Murray.

To Murray and Julie’s amazement, business increased considerably after Radio New Zealand’s programme, Country Life, aired in 2020.

"We sold $15–20,000 worth of jerseys as a result of that programme. We were up until 11pm every night packaging jerseys. We received enquiries from listeners that included people who hadn’t had anything to do with wool before. As a result, we broke into a different market."

Marketing their product has primarily been an organic process.

"I guess the marketing has developed easily, partly because everyone is not too happy about the low prices farmers get for wool. The pandemic and subsequent lockdowns probably helped, too, because, as a result, people want to support New Zealand and be able to wear a natural product.

"Those factors have lined up to make the marketing side easier for us. We are growing steadily; we probably wouldn’t want to grow any faster because it’s important to keep up with what we have on now."

Their main ambition says Murray is to keep developing quality products.

"As long as we keep New Zealand happy, that’s the plan, and possibly we’ll look off-shore, in the long term."

Most popular styles

|

|

From shearing shed to knitwear production, it all began here

|

According to Murray, their most popular jerseys are the navy and charcoal collared ones, with the younger generation preferring the hooded style. A school is thinking of adding the warm jerseys to their uniform requirement.

"We’ve got a small school looking at coming on-board, which is good. I hope the younger generation will see wool is not the old itchy, homespun jersey that it used to be but instead a product that can be made into some nice stuff. Whether it’s Icebreaker or Mons Royale, there are some beautiful woollen products out there."

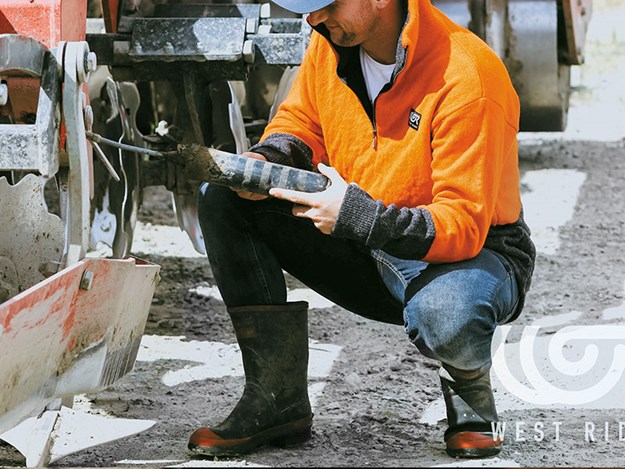

West Ridge also produces a jersey in high-visibility orange, though, Murray adds, it’s not bright enough for the government high-vis standard. He notes that’s ironic because a high-visibility polar fleece garment would go up in a heartbeat if it caught fire, whereas wool wouldn’t.

The jerseys are made from 30-micron Perendale wool, with an inner shell of merino wool to make them soft and cosy. The jerseys undergo a unique process to make them easy-care.

"All you need to do is throw the jersey in the washing machine on the delicate cycle," explains Murray.

Feedback from farmers

|

|

High-vis clothing gives added protection to workers in high danger areas

|

When asked whether he gets an appreciative slap on the back for his initiative when he goes to the local pub, Murray says that farmers are just happy that someone is doing something.

"They love the product, and they are happy that someone has had a crack at promoting wool; that someone is trying to do something even on a small scale."

The benefits of wool![]()

|

|

30 micron Perendale fleece

|

Murray is happy that his idea has taken flight.

"Wool is such a good thing to wear. We need more people in the media informing others about the benefits of wool. There are still those who think that when the wool is cut from the sheep, it dies. They don’t realise if sheep are shorn every six months, they put on weight and thrive."

With sheep shorn twice a year and the shearers busy, there’s a flow-on effect for the economy, too.

"Every small town in New Zealand hums as a result because people are spending money in the local shops, garages, and pubs. That’s what our government needs to remember when it comes to promoting the wool industry."

The future of wool

|

|

The West Ridge brand is making a name for itself

|

When asked where he’d like to see the wool industry in New Zealand going, Murray replies, "Just anywhere up".

"I’d like to see insulation and carpets for a start. But besides these, there are many things we can use wool for. Many folks think we need to get complicated with it but what we’ve done is certainly not complicated. There have been woollen jerseys around forever; we just did it slightly different and in a modern way. People went away from wool for years.

"When I was young, polar fleece came in, and everyone began wearing it. It’s a shame it was allowed to be called fleece because it’s not a fleece. Ideally, I’d like the government to put a surcharge on it when it comes to the country because once you have finished with it, it doesn’t wear out or rot down like wool. With wool, you can take your jersey off when it’s worn out and put it in your vegetable garden, and it will compost nicely."

Recently, when Murray was at a local working bee, a fellow worker picked up a little bird’s nest and showed him and it was lined with wool.

"How about that? They know a thing or two, don’t they?"

Find new and used farm machinery for sale in NZ

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpg)

.jpg)

.jpg)

.jpg)