Strautmann Giga-Vitesse Wagon

|

|

|

|

|

|

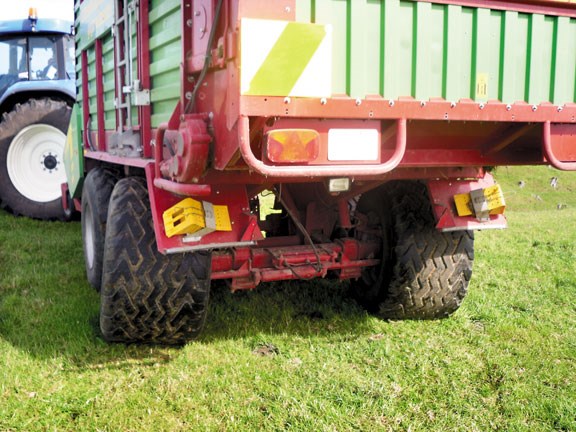

The Strautmann Giga-Vitesse loader wagon has impressive build quality and easy maintenance

|

|

Strautmann Giga-Vitesse Wagon

|

- Excellent build quality

- Easy maintenance of moving parts

- Direct drive from the gearbox to the rotor eliminates breakages

- Adjustable auto loading

- Electro-hydraulic controls and load sensing hydraulics

Loader wagon technology has come a long way over the past 20 years – not only have they grown bigger and stronger, but the major improvements have been in the axle configuration to accommodate the bigger and faster tractors. The other area of improvement is the chopping ability, which has allowed large quantities of grass to be packed into the wagons.

Owner Marc Gopperth runs a medium to large-scale contracting business in coastal Taranaki. As far as heavily constructed farm machinery goes, it doesn’t come much stronger than Strautmann, aswhere the build quality of these machines cannot be questioned.

Marc feels that due to the rougher terrain of some coastal Taranaki land and the ability of with the farmer to roll their own pit, they have excellent flexibility where they can split them up and do two or three jobs at once and still maintain excellent compaction at the stack.

Another benefit of the wagons is they can be used as high-capacity maize silage trailers later on in the season by simply removing the top bungy cords.

The control box

This works in with the load-sensing hydraulics to give precise and responsive movements. I was impressed with how very simple but reliable the control panel was. There are nine switches, which allows you to carry out basic functions like; lift and lower the pick up, open the door, engage auto loading etc,etc.

A large dial allows you to adjust the speed of the floor while auto loading and unloading at the pit. Three red lights in the left-hand corner of the control box show if one of the knives has been knocked out by a foreign object, and once the tail buzzer is tripped to indicate the wagon is full.

Hydraulic drawbar

The major benefit of the hydraulic drawbar is to prevent the pick-up being damaged when driving over the stack. This also is advantageous when in paddocks with humps and hollows because you can lift or lower the double- acting cylinders to prevent the pick-up from bottoming out on the ground. All Giga-Vitesse wagons are equipped with hydraulic suspension of the drawbar though nitrogen-filled shock absorbers.

Pick-up

In addition to a slightly narrower pick-up (1.90m width), six6 tine rows enable a clean pick-up of the swath and the build strength to ensure minimal down time.

The pick-up is easily visible from the cab and works in a pendulous fashion forward. You could argue that if you did hit an obstacle the pick-up will swing out of the way, but t,the obvious pitfall of this is vision impairment.

The pick-up wheels are heavily built yet flexible enough to allow adaptation to the undulating contour of most paddocks. Another useful feature is the galvanised windrow roller, providing provides a smooth and even pick-up of the swath, which isand this useful in light crops when it is windy.

Gear box

The drive shaft, which is centrally located in the pipe of the drawbar, drives the high-dimensioned gearbox that sits sideways. It doesn't need any maintenance at all.

The biggest benefit of the Giga-Vitesse over its predecessor is the direct drive gears rather then chain drive so the power is optimally transferred to the rotor, causing and maintenance and down time costs to beare reduced.

Rotor

The rotor is set spirally with eight8 tine rows. The hardened steel tine plates, which are welded on at the ends,, these have minimal wear and tear and areis a benefit over some of the competitors’ models. The spiral tines allow easy and clean cutting of the crop because of their width.

Strautmann has designed a cutting unit that can be dropped out of the rotor by two hydraulic rams,which meanings blockages can be sorted out easily. Forty-one knives are located on one level and provide a consistent crop cutting of between 35-39mm. All blades have a ripple grinding and double cutting edges.

Knife protection is a key area, as replacing these is not a cheap exercise. Strautmann has a unique protection system of the tripping the knives out when a foreign object touches the blade. The knives are spring-loaded in such a way that the energy is nearly identical at any point of the blade, so no matter where the blade gets hit it will kick back to avoid expensive damage.

Floor chains

Another improvement is the double row of floor bars with four rows of chains that are rated to15 tonne per chain. This reduces the stress on the bars, chains and drive unit.

Automatic tensioners ensure appropriate chain tension at all times. The chains are driven by a two-stage hydraulic motor located at the rear of the wagon and areis well protected by a steel bar to combat any potential damage from rougue strainer posts.

Tail door

Another great feature is the mechanical locking of the tail door, which guarantees safe transportation of the load and reduces lost crop. Hydraulic rams initially lift the tailgate vertically, which unlocks the door to open, swinging high to allow the load to be quickly spread over the stack for quicker turn around time.

Automatic loading device

Standard on most loader wagons, the benefit I found with the Strautmann auto loading feature is that the sensitivity of the switch can be varied by the continuous adjustment of the transport floor to achieve the desired loading result.

Steering axle

All Giga-Vitesse wagons have aas standard tandem trailing steering axle. This means there iswith no scuffing of the turf pasture and that the wear and tear of the tyres caused by turns on solid ground is minimised. The only down side of this is that you can do serious damage to the steering axle if you back up while the steering is activated.

Read in-depth farm machinery reviews in the latest issue of Farm Trader magazine, on sale now.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpg)

.jpg)

.jpg)