Pasture care: Amazone UX 4200 Super ISOBUS

The covered valve bank is mounted above the boom, out of harm’s way, and a external pressure washing hose makes for easy cleaning.

The covered valve bank is mounted above the boom, out of harm’s way, and a external pressure washing hose makes for easy cleaning.

An automatic hydraulic sequence takes care of folding the boom which when folded sits neatly along the top of the tank to keep the overall width to 2.4m.

An automatic hydraulic sequence takes care of folding the boom which when folded sits neatly along the top of the tank to keep the overall width to 2.4m.

Twin freshwater tanks are cleverly incorporated into the sides of the main tank with a capacity of 550 litres.

Twin freshwater tanks are cleverly incorporated into the sides of the main tank with a capacity of 550 litres.

Ultrasonic sensors on the boom maintain the height above the crop, regardless of the contour, with skids as a back-up.

Ultrasonic sensors on the boom maintain the height above the crop, regardless of the contour, with skids as a back-up.

The control station cleverly gives complete control over the sprayer, whilst the sealed storage locker provides space for chemicals and protective clothing.

The control station cleverly gives complete control over the sprayer, whilst the sealed storage locker provides space for chemicals and protective clothing.

An access platform at the front of the machine, with a fold-down ladder, gives access to the lid on top of the tank.

An access platform at the front of the machine, with a fold-down ladder, gives access to the lid on top of the tank.

The unique shape of the main tank lowers the centre of gravity, increasing the stability on slopes.

The unique shape of the main tank lowers the centre of gravity, increasing the stability on slopes.

The Amatron box, the Fendts ISOBUS touch screen, and the joystick give the operator precise control.

The Amatron box, the Fendts ISOBUS touch screen, and the joystick give the operator precise control.

|

|

The covered valve bank is mounted above the boom, out of harm’s way, and a external pressure washing hose makes for easy cleaning.

|

|

|

An automatic hydraulic sequence takes care of folding the boom which when folded sits neatly along the top of the tank to keep the overall width to 2.4m.

|

|

|

Twin freshwater tanks are cleverly incorporated into the sides of the main tank with a capacity of 550 litres.

|

|

|

Ultrasonic sensors on the boom maintain the height above the crop, regardless of the contour, with skids as a back-up.

|

|

|

The control station cleverly gives complete control over the sprayer, whilst the sealed storage locker provides space for chemicals and protective clothing.

|

|

|

An access platform at the front of the machine, with a fold-down ladder, gives access to the lid on top of the tank.

|

|

|

The unique shape of the main tank lowers the centre of gravity, increasing the stability on slopes.

|

|

|

The Amatron box, the Fendts ISOBUS touch screen, and the joystick give the operator precise control.

|

The new Amazone UX 4200 Super sprayer with ISOBUS is sure to impress farmers and contractors across the country with its range of features aimed at improving results while keeping things simple for the operator.

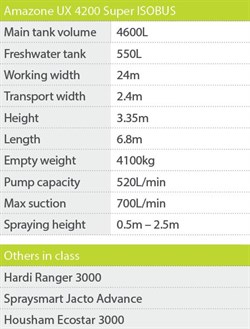

This month I tested the new Amazone UX 4200 trailing sprayer, recently sold by Claas Harvest Centre to Bethall Agriculture, a company farming most of the land around Weka Pass. On the day of the test the sprayer was coupled with a Fendt 824, which was more than adequate and probably the nicest spray tractor I have come across.

Tank

The main tank on the sprayer is a very unique and distinguishable pear-shaped plastic tank with a capacity of around 4600 litres. The design and shape has been well thought out by Amazone to offer some key benefits. Most importantly, in the case of Bethalls Agriculture, this unique shape keeps the weight of the full tank down low and will disperse the movement of the liquid inside. The sump at the bottom of the tank means all the liquid can be used, regardless of the angle of the sprayer. Also, the fact that all the sides of the tank are rounded not only means it's an easy shape to clean internally and externally, but also that it's an easy tank to agitate and mix chemicals in. Both these functions are taken care of with three high-pressure rotating jets in the bottom of the tank. A high-pressure hose and gun on the back of the machine is great to see, allowing for cleaning the machine while still out on the job.

In addition to the main tank, the sprayer can hold 550 litres of freshwater in two tanks, used for washing and rinsing purposes. A smaller 20-litre tank at the front will ensure there is always clean water on hand for the operator to wash their hands. The induction hopper on the side folds down about a metre off the ground to make loading and mixing chemicals a breeze.

Inside this hopper is a jet ring to ensure all chemicals are washed out of the induction hopper, while a handy bottle wash jet makes rinsing containers easy. An enviro-drum coupling makes sucking larger quantities of chemicals out of suitable drums easy. A plastic storage locker also provides two compartments for spray containers and protective clothing.

Chassis

A robust steel frame is used to carry the tank and the boom, starting at the front the substantial drawbar, incorporates a hydraulic jack to make hitching and unhitching simple. A hinge point, with rubber blocks where the drawbar meets the chassis, provides adequate suspension to ensure a smooth ride. To the rear of the chassis, the axle sits directly under the arms that the boom mounts to. This keeps the weight of the machine evenly balanced between the drawbar and the axle.

Fitted under the chassis of this machine was Amazone's top of the line TrailTron steering axle system. This uses hydraulic rams to steer the wheels of the sprayer, which is coupled with an ISOBUS connection, and software that matches the tracking of the sprayer to the tractor from the movement of the tractor's front wheels. This is an outstanding system that can be calibrated to any tractor and overridden if necessary for manual correction on hills. The system has advantages over a steering drawbar, as it provides better stability on hills, and the boom will line up square at the start of each run.

Fitted under the chassis of this machine was Amazone's top of the line TrailTron steering axle system. This uses hydraulic rams to steer the wheels of the sprayer, which is coupled with an ISOBUS connection, and software that matches the tracking of the sprayer to the tractor from the movement of the tractor's front wheels. This is an outstanding system that can be calibrated to any tractor and overridden if necessary for manual correction on hills. The system has advantages over a steering drawbar, as it provides better stability on hills, and the boom will line up square at the start of each run.

As with most machines, there is a massive range of options as far as tyres and rims go. The test sprayer was fitted with 520/85 R42, which are more than adequate and give a ground clearance over 800mm. Commercial running gear and load-sensing hydraulic drum brakes mean the sprayer can towed fully loaded safely on the road at up 50kph. Good-sized mudguards haven't been overlooked by Amazone and will keep the machine tidy whatever the conditions. Although not fitted to this machine, adjustable wheel track width is available as an option.

Pump

Sitting up the front on the drawbar, out of the way, are the two diaphragm pumps that run the sprayer and have a combined output of 520 litres per minute. It's great to see Amazone has done away with an annoying PTO shaft and opted for hydraulically-driven pumps. When spraying, one pump is used to pressurise the boom, while the other is used solely to provide agitation in the main tank, keeping chemicals well mixed. The speed of the pump used for agitation can be varied infinitely — handy if using chemicals with a tendency to foam up with too much agitation.

It's when it comes to filling the sprayer that the twin pump system really pays off, with a three-inch filling port and a venturi system the sprayer can fill itself from a sufficient water source at a massive 700 litres per minute, saving time and allowing the operator to get on with the job.

Boom

As usual, a range of boom types and sizes are available from Amazone, with our test machine featuring a 24-metre Super L boom. This boom hydraulically folds up automatically from the cab and amazingly, when folded, sits within the shape of the tank to keep the transport width down to 2.4 metres.

When folded, the boom locks itself to the boom mount to prevent movement, while hydraulic accumulators on the lift rams between the boom mount and the chassis provides suspension, even when folded in the transport position.

The boom uses a pendulum mount with spring dampers to minimise yaw and vertical movement, and hydraulic profi-folding rams allow either side of the boom to be lifted independently. When fitted with distance control, as this particular machine was, an ultrasonic sensor on each side of the boom is used to maintain the boom at a pre-set height above the crop — an excellent feature in undulating terrain. Auto-lift lifts the boom automatically at the headlands, when the nozzles are shut off to prevent damage, then lowers it again to begin spraying. Spring-loaded breakaway on the end sections of the boom and hydraulic breakaway on the second section will help limit damage if an obstacle is struck.

Section control divides the nozzles on the boom into seven sections that can be turned off manually or automatically. The valve block to control this is mounted on top of the centre of the boom, out of harm's way. Re-circulating spray lines on the boom ensure the spray is at the nozzles and runs right to the end of the boom, so it's ready to go with no lag when you start spraying. It also eliminates residues settling in the boom. During cleaning, freshwater is flushed through the lines to the nozzles and back into the tank. Triple body nozzles are used to give a wide range of application rates, while LED striplights, down the length of the boom behind the spray fan, make it possible to spray at any time of the day.

Controls

Manual control taps on the sprayer are grouped together on the left-hand-side operator station and make it easy to get your head around what could be quite a complex system on the sprayer. Quite simply there are two main levers that control suction and pressure. The suction control decides where the two pumps will draw from, either the main tank, freshwater tank or the filling port, while the pressure control tap has four positions that decide where the liquid is going to — boom for spraying, main tank for filling, the induction hopper or the wash equipment.

A clever idea from Amazone is a steel plate behind the pressure control tap that turns with it, giving access only to further controls able to be used in each position and prevent the wrong taps being turned. In-line filters, situated here, can be flushed with freshwater or accessed even with the main tank full. Further controls on the induction hopper are easy to use, and a mechanical tank level gauge shows the amount of liquid in the main tank.

Up in the cab is where the controls start to get really impressive. Having an ISOBUS connection means the main controls were displayed through the big Fendt's clear touchscreen ISOBUS terminal, which can display almost anything you could wish to know about the sprayer, including the amount of liquid left in the tank and how far it will go at the current rate, ground speed, application rate, boom height, and section control, to list a few. It also gives control over all operations of the sprayer mentioned, such as the distance control and auto-lift on the boom, auto-folding of the boom and the Trailtron steering axle.

When fitted with the comfort package, many of the manual controls on the sprayer can also be controlled from the cab, such as the agitation and cleaning cycle, along with filling — the exact mount of water needed can be entered, and the pump will stop when it has taken that amount on board. An optional multifunction joystick included in the test machine uses eight buttons to give the operator precise finger tip control of many of the commonly-used functions.

With the control of the sprayer on the ISOBUS screen, this leaves the Amatron 3 screen (Amazone's high-resolution, six-inch screen) free to run GPS guidance and control of the sprayer in conjunction with the Topcon setup on the Fendt. As you would expect, this controls the pressure to meet the target application rate, automatically turns the sprayer on/off at the headlands, sections off when they over lap, and much more. Like most GPS units, this can store multiple jobs you have coming up or jobs completed, and files can be exported via a USB connection and overlaid on maps for records.

Verdict

The UX 4200 Super sprayer is an excellent example of a high capacity sprayer that, when fitted with nearly all the options like the machine I tested, pretty much ticks all the boxes for anyone with a lot of ground to cover.

Everywhere you look on the sprayer you can tell Amazone has put a lot of thought into what would make the task at hand easier and simpler for the operator, without any compromises. It's great to see the incorporation of technology, such as ISOBUS control, ultrasonic sensors, and GPS, all integrated seamlessly, while ensuring the machine is simple to operate. The boom, tank, twin pumps, and all the controls rate fairly highly in comparison with anything else I've seen. So what are the drawbacks? Well, nothing really. The only reason I can see for not purchasing this sprayer is justifying the price tag, but then you really do get what you pay for.

Positives

- Unique-shaped smooth tank to aid with agitation and cleaning, whilst keeping the centre of gravity low

- TrailTron steering axle improves the stability and accuracy of sprayer

- Excellent 24m boom set up with auto-folding, superb damping, and suspension

- Distance control with ultra sound sensors for auto boom-height control and auto-lift on headlands

- Well laid-out control station simplifies operation

- Induction hopper for mixing chemicals

- ISOBUS connection integrates the sprayer with the tractor, along with a comfort package and multifunction joystick for precise control

- GPS guidance and compatibility

Negatives

- The price tag, but you definitely get what you pay for

- Trailing vs self-propelled will largely come down to the individual's situation

For the latest reviews, subscribe to our Farm Trader magazine here.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpg)

.jpg)

.jpg)