Test: Lely Tigo 60 R Wagon

Unloading is easy with an automatic unloading sequence activated from the control box at the push of a button

Unloading is easy with an automatic unloading sequence activated from the control box at the push of a button

Two sets of floor chains ensure that even the wettest and heaviest loads are moved to the back of the machine

Two sets of floor chains ensure that even the wettest and heaviest loads are moved to the back of the machine

A simple easy-to-use control box is well laid out, with clearly labelled buttons to control all functions

A simple easy-to-use control box is well laid out, with clearly labelled buttons to control all functions

The John Deere 6190R on the front provided more than enough muscle for the task at hand

The John Deere 6190R on the front provided more than enough muscle for the task at hand

There is exceptionally good access to the knife bank when it is unlatched and swung out to the side of the machine

There is exceptionally good access to the knife bank when it is unlatched and swung out to the side of the machine

A heavy-duty spiral rotor is gear driven for reliability and forces the material across the knives, straight up into the bin

A heavy-duty spiral rotor is gear driven for reliability and forces the material across the knives, straight up into the bin

The two matching Lely Tigo 60 R profi wagons, operated by Elsworth Agriculture, can move a serious amount of silage economically in a short amount of time

The two matching Lely Tigo 60 R profi wagons, operated by Elsworth Agriculture, can move a serious amount of silage economically in a short amount of time

A large steel roller under the centre of the pickup ensures it follows the ground without bottoming out on undulating terrain

A large steel roller under the centre of the pickup ensures it follows the ground without bottoming out on undulating terrain

|

|

Unloading is easy with an automatic unloading sequence activated from the control box at the push of a button

|

|

|

Two sets of floor chains ensure that even the wettest and heaviest loads are moved to the back of the machine

|

|

|

A simple easy-to-use control box is well laid out, with clearly labelled buttons to control all functions

|

|

|

The John Deere 6190R on the front provided more than enough muscle for the task at hand

|

|

|

There is exceptionally good access to the knife bank when it is unlatched and swung out to the side of the machine

|

|

|

A heavy-duty spiral rotor is gear driven for reliability and forces the material across the knives, straight up into the bin

|

|

|

The two matching Lely Tigo 60 R profi wagons, operated by Elsworth Agriculture, can move a serious amount of silage economically in a short amount of time

|

|

|

A large steel roller under the centre of the pickup ensures it follows the ground without bottoming out on undulating terrain

|

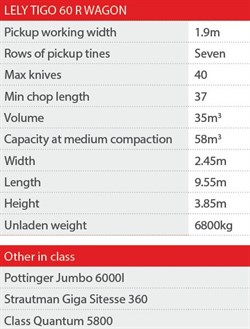

Brent Lilley headed down to Reporoa to check out two Lely Tigo 60R Profi loader wagons that are proving you can have a quality wagon that’s both economic and efficient.

The two test Lely Tigo 60 R Wagons, owned by Reporoa-based Elsworth Agricultural Contractors Ltd, work between Taupo and Rotorua on challenging terrain that has also seen a massive influx of dairy conversions during the past 10 years.

Elsworth operates a fleet of seven John Deere tractors and has a wide range of equipment to cover all contracting requirements, including hay, silage, cultivation, earthworks, and two triple disc drills for seeding. Owner Ian Elsworth, with over 40 years of contracting experience, purchased two Lely Tigo 60 R wagons in October last year to replace his previous wagons of another brand — a move he didn't take lightly.

The two Lely wagons have now cleared over 2500 hectares between them — no easy task in this part of the country — and the guys at Elsworth Contracting have been so impressed they have recently purchased a third Lely wagon for next season. The wagon was set up with a John Deere 6190 R on the front, which proved more than adequate for this size of wagon.

Ian's son, Lance, has been driving it most of the season now and is more than happy to share his thoughts and experiences of the Lely with me. The machines were sold by Giltrap AgriZone in Rotorua, a company that Ian says is very easy to deal with and provides excellent parts and service. Salesman Harry Murdoch was on hand on the day of the test with a wealth of experience and knowledge to answer any questions about the machine.

Pickup

Up the front is a well-designed pickup, a crucial part of any loader wagon, and Lely has kept to the forefront with its design. Those of you who have spent time laying under a pickup, taking skin off your knuckles while repairing it, will be happy to see fixed tine bars and the absence of a cam track, to cut down on maintenance. Heavy-duty tines are spaced 54mm apart and there are an impressive seven rows to ensure a tidy job, even at high ground speeds. Although I didn't strip the pickup apart to see it, a tine loss protection system is incorporated to prevent broken tines rattling around inside. Galvanised bands are an excellent idea and should extend their lifespan considerably. Their unique shape ensures a clean crop flow. The 1.9-metre width of the pickup is adequate to handle a fairly wide row while keeping the machine manoeuvrable though gate ways.

One of the first things you notice about the pickup when the machine is working is just how quiet it is — you can barely hear any noise at all. It was doing a good job clearing the shorter second-cut grass off the paddock cleanly. Like most machines, pivoting caster wheels on the sides minimise scuffing when turning, and can be adjusted easily to set the height. A floating frame design allows the pickup to freely move up, down, and side to side with the contours of the ground.

One of the first things you notice about the pickup when the machine is working is just how quiet it is — you can barely hear any noise at all. It was doing a good job clearing the shorter second-cut grass off the paddock cleanly. Like most machines, pivoting caster wheels on the sides minimise scuffing when turning, and can be adjusted easily to set the height. A floating frame design allows the pickup to freely move up, down, and side to side with the contours of the ground.

The real stand-out feature is this machine's smooth ground-hugging ability, thanks to its large steel roller in the centre behind the pickup. This follows the ground and prevents it from ever bottoming out. An adjustable windguard uses a roller to ensure the crop is fed evenly into the machine, although it was suggested this could do with some further adjustment to prevent the crop balling up in very light crops.

Rotor

The first thing you notice about the rotor is its placement in relation to the pickup, which really impressed me. It sits right behind and above the pickup to drag the grass off the tines and into the machine, without slowing down or jamming. The rotor itself is a hefty solid-looking design, using seven rows of points in a spiral shape to move the grass across the knives, with minimal power requirement, and straight up into the machine. The points are in replaceable sections and use a 25mm flat steel face to push the material smoothly across the knives, with little wrapping or jamming. Drive for the rotor comes directly from the main PTO-driven gearbox, through oil immersed gears, to the rotor. This creates minimal power losses, low maintenance, and increased reliability.

Forty knives are spread across the width of the feed channel to give the machine a theoretical chop length of 37mm. Although, as they are in two banks, it's simple to run with half the knives in (like the machine on the day) to give a chop length of just over 70mm.

Each knife is mounted on an individual spring system to allow it to move out of the way of any foreign objects with minimal damage. The knife banks can be control from the cab of the tractor, or with handy buttons on the side of the wagon. But what impressed me the most was the accessabilty of the knives. With the knives out of the feed channel, the entire knife bank can be unlocked and then swung out to the left-hand side of the machine, all without tools.

However, when grass builds up under the knife bank it needs to be cleared out regularly by hand, and this is a pain. Also, the knives on our tester are only single-sided, rather than double like on most other machines, which cuts down sharpening intervals.

Chassis

Chassis

Galvanised channel steel makes up the main chassis and encases the wooden floor of the load bed. Two sets of 10mm floor chains and slate are used to move even the heaviest loads towards the rear of the machine via a single hydraulically-driven drive motor at the rear. The hefty drawbar at the front of the machine uses a hydraulic ram to adjust the level of the machine when loading or unloading and includes an accumulator to provide drawbar suspension. Channel iron uprights and pressed sheet metal make up the superstructure of the bin itself. Bars across the top of the bin add to its strength and wire ropes keep heavily-compacted loads in, although they will prove to be a hindrance if you intend on using the machine as a bin trailer.

The running gear under the chassis uses a tandem hydro-pneumatic suspension setup, which is excellent to see, in my opinion. This incorporates four hydraulic cylinders to mount the two axles to the chassis. Each cylinder includes an accumulator for suspension and allows the wheels to move independently. The clever part is that they are connected, so they will also work together to maintain a constant height and keep the machine stable, regardless of the load or ground conditions. The drivers at Elsworth Contracting have found this to be an excellent setup that makes the wagon more stable than their older machines on hills, even though they are much larger. Commercial axles and hydraulic load-sensing drum brakes ensure heavy loads can be towed and stopped safely at high speeds. Nice wide 710 /40 R 22.5 tyres on this machine keep compaction down to a minimum out in the paddock, although, as usual, there is range of tyre options. Fitted as standard to these machines are profi specs.

A hydraulic trailing steering back axle prevents scuffing in the paddock and is exceptionally helpful when negotiating tight gateways — this can be locked for safety, when required, from the cab of the tractor.

Controls

The standard control box on this machine uses a large membrane panel that features buttons with corresponding symbols, grouped together in a logical pattern, with loading at the top, unloading at the bottom, and anything else in the centre, making it very simple and easy to use. A diagram of the wagon with display lights at the very top is handy to see what functions are activated, and a counter at the bottom makes it easy to keep track of the quantity of silage shifted. Whilst this standard control box is more than adequate and very simple to use, it is quite large and has no display screen — an option for an ISOBUS control box is probably well worth the extra outlay.

As the machine uses a power beyond coupling on the tractor, with electronic control valves on the wagon, oil is only drawn as required, minimising overheating and power losses.

Auto-load and unload is a feature that comes standard on the profi model wagons and is definately well worth a mention. This is activated on the control box and has two compaction settings — medium and heavy. This uses two separate sensors on the top panel at the front of the machine to determine how much material the rotor packs in before the floor is automatically moved backwards. A pressure sensor in the lift rams of the back door lets the machine know when the bin is full and prevents the floor being moved any further. An audible alarm also alerts the driver. In practice, the driver's use this function most of the time, as it makes loading the wagon a breeze and delivers consistent load sizes all day.

Summary

For those requiring a loader wagon to use solely to pick up grass silage (and not as a bin trailer), the Lely Tigo 60R Profi could be well suited to your operation. Stand-out features include a super quiet cam-less pickup that does an exceptional job, even at high forward speeds; an easily-accessed knife bank that swings out from under the machine; hydro-pneumatic suspension for stability; and an exceptional auto-loading mechanism. Strategic use of galvanised components should give an increased lifespan to this well-built machine and a directly gear-driven rotor minimises maintenance issues.

The build-up of material under the knife bank, and in a few other dead-end spots around the machine, is a minor issue that could be easily remedied by Lely.

All in all, a top quality machine that is a perfect fit for Elsworth Contracting's requirements — namely to harvest grass silage as efficiently and economically as possible.

Positives

- Camless pickup with seven tine bars

- Directly gear-driven rotor, optimally positioned above the pickup

- Strategic use of galvanised steel on corrosive areas

- Knife bank folds out from under the machine for easy access

- Hydro-pneumatic suspension and a steering axle for stability and a smooth ride

- Auto-loading and unloading

Negatives

- Grass builds up under the knives and needs to be cleaned out

- Single-sided knives

- Bars and ropes on the top of the bin make this machine largely a one-trick pony

For the latest reviews, subscribe to our Farm Trader magazine here.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpg)

.jpg)

.jpg)

.jpg)