Test: Quivogue Jupiter Chisel Plough

The Jupiter had excellent trash-clearing ability given the number of rear finger harrows.

The Jupiter had excellent trash-clearing ability given the number of rear finger harrows.

You can see the wings fold in very close to the centre of the machine, which keeps the tines within 3m for transport.

You can see the wings fold in very close to the centre of the machine, which keeps the tines within 3m for transport.

The aggression of the finger harrows is adjusted using hand screws similar to a toplink.

The aggression of the finger harrows is adjusted using hand screws similar to a toplink.

The 6.3m working width will allow you to cover some ground in a day, although you will need the best part of 250hp to achieve a reasonable ground speed.

The 6.3m working width will allow you to cover some ground in a day, although you will need the best part of 250hp to achieve a reasonable ground speed.

The heavy-duty lift rams move the machine from transport to working position. Ram shims control working depth.

The heavy-duty lift rams move the machine from transport to working position. Ram shims control working depth.

The outer contour-following wheels are manually adjusted again using a toplink type mechanism.

The outer contour-following wheels are manually adjusted again using a toplink type mechanism.

The heavy-duty frame is built to last, plus the hydraulic transport latches make it very stable during transport.

The heavy-duty frame is built to last, plus the hydraulic transport latches make it very stable during transport.

The close-to-centre folding wings allow very narrow transport width.

The close-to-centre folding wings allow very narrow transport width.

The main wheels on the machine run on a walking beam, which is excellent at following the contour of the paddock.

The main wheels on the machine run on a walking beam, which is excellent at following the contour of the paddock.

|

|

|

The Jupiter had excellent trash-clearing ability given the number of rear finger harrows.

|

|

|

You can see the wings fold in very close to the centre of the machine, which keeps the tines within 3m for transport.

|

|

|

The aggression of the finger harrows is adjusted using hand screws similar to a toplink.

|

|

|

The 6.3m working width will allow you to cover some ground in a day, although you will need the best part of 250hp to achieve a reasonable ground speed.

|

|

|

The heavy-duty lift rams move the machine from transport to working position. Ram shims control working depth.

|

|

|

The outer contour-following wheels are manually adjusted again using a toplink type mechanism.

|

|

|

The heavy-duty frame is built to last, plus the hydraulic transport latches make it very stable during transport.

|

|

|

The close-to-centre folding wings allow very narrow transport width.

|

|

|

The main wheels on the machine run on a walking beam, which is excellent at following the contour of the paddock.

|

This month Jaiden tests the Quivogne Jupiter Chisel Plough, a French-made cultivator that is easier to pull than a set of rippers, and covers more ground quicker than a plough.

At this time of year Canterbury usually looks like a desert, but instead, it looked as good as I have ever seen it and there are two reasons you can tell they are doing well. The first is that some farmers haven't had the irrigators going for six weeks, and the second is the road sides are covered in lush, clover-filled grass.

Although this is great for the dairy and beef farmers in the region, it has been somewhat of a nightmare for the cropping folk. Luckily I tested a machine that might make their lives easier post-harvest, which will make up for some of the frustration.

About Quivogne

Farm Chief is the New Zealand importer and distributer of the Quivogne brand of farm machinery. Quivogne is manufactured in France and has been in business for over 60 years, specialising in cultivation equipment with a number of tine, disc, and roller implements on offer.

The Quivogne group is 100-percent family owned, with all its machines designed, built, and tested at its Jussey and Polaincourt production sites in eastern France. They have extensive R&D programs and a thorough testing facility, which is good to know when these machines have been shipped half way around the world.

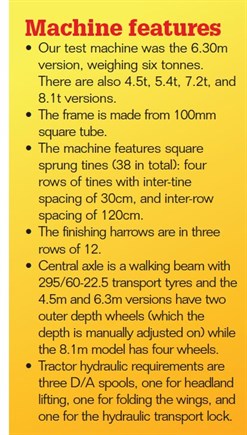

The company's latest offering is this month's test machine, the 6.3m Jupiter Chisel Plough, a new trailed cultivator with a large working width and heavy tine harrows at the rear.

Overview of the Quivogne Jupiter Chisel Plough

Initially I was certain the 315hp John Deere tractor we had on hand would easily pull this machine through the ground but, when put into practice, the cultivator really did get the soil moving and with the tractor tapped at 10kph, it was just as well we had that many ponies under its bonnet.

We were working in heavy trash straight after the combine. To be fair, it probably wasn't the right tool for the paddock in which it was being used (that's not to say it was doing a bad job), but the trash needed chopping up with a set of discs or ploughing to get rid of the residue.

This machine would be excellent in ground straight out of winter, where you wanted something to break up the hard soil, as ploughing can often break the soil into concrete-sized blocks and ripping can be like pulling through the road. This machine will give you the best of both worlds — easier to pull than a set of rippers, and you can cover ground much faster than with a plough.

The Jupiter is effective because of its long frame with its tines widely spaced apart, meaning the residue is intensively mixed before settling, and allows the three rows of 12mm levelling fingers to create a smooth finish.

Depending on the soil type, you would probably want to roll after this machine as there will still be some fist-size lumps that will make their way through. If you had the rear drawbar attachment as well as a roller behind, it could be a primary cultivation and finishing tool all-in-one.

How the Jupiter Chisel Plough works

The Jupiter is manoeuvrable in the paddock due to the four large 295/60 R22.5 transport wheels and when lowered for work, ram shims take care of the depth control. These wheels are on a walking beam setup and hold the weight of the machine in the paddock, allowing the walking beam to travel over humps and hollows with relative ease.

If the front to rear level of the machine needs to be altered, this is done simply by undoing a couple of large nuts and hand screwing the stopper for the spring either forward or back. This simplicity is an attractive feature of this machine.

This is the same with the levelling tines on the rear of the machine — again hand screws will change the aggression, although I felt a slotted bolt system may have been easier to use in the future as the screw will no doubt get clogged with dust and grease.

Another potential problem was the lack of shear bolt protection on the legs. Each had its own spring break-back system, but if the machine hits an object in the ground big enough, something more expensive will end up breaking.

The verdict

When it comes to cultivation machines, there is no one machine that will suit all conditions and all soil types. To be fair, the sticky soil during our test may have contributed to the machine allowing fist-sized clods to pass through the tine harrows.

The ability to attach a drawbar and pull a roller will allow the Jupiter to be more of a one-pass machine, and with the working width of both this and its big brother, they'll have you doing half the neighbourhood before you know it.

The Jupiter is a very well-built machine with nice simple features that make it easy to operate and adjust in changing conditions. The walking beam central carriage and the wings that fold from the centre allow the machine to fold up neatly for road transport.

All in all, I've not much to complain about.

Pros

- Heavy-duty construction

- Easy front-to-back manual adjustment

- Large tyres and walking beam make the machine stable and smooth to tow on the road and follow the contour nicely in the field

- Tine spacing is wide enough to cover the ground effectively, yet offers very good trash flow

- The wings fold from in the centre, rather than outside the transport wheels, which keeps the tines well within the 3m transport width

- Hydraulic transport lock

- Spring-loaded legs allow them to move up and back if an object is hit

Cons

- The drawbar sits very low where it is mounted to the machine and would catch knobs in undulating terrain

- Mechanical adjustment of rear tines using treaded bolts is good for simplicity, but will eventually fill up with dirt and dust and set like concrete

- No shear bolt protection on the legs

For the latest reviews of farm machinery, subscribe to Farm Trader magazine here.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpg)

.jpg)

.jpg)