Review: Taege Six Meter Airseeder

'S' shaped spring tine mount onto the box section that is rotating forward. This causes the tines to pull themselves into the ground with little downforce.

'S' shaped spring tine mount onto the box section that is rotating forward. This causes the tines to pull themselves into the ground with little downforce.

The drill and tyre roller following behind both feature impressive contour following, with a simple slotted hole on the folding arms.

The drill and tyre roller following behind both feature impressive contour following, with a simple slotted hole on the folding arms.

Heavy-duty phasing rams on the wheels lift all the sections evenly and are used to control the depth of the drill with simple ram shins.

Heavy-duty phasing rams on the wheels lift all the sections evenly and are used to control the depth of the drill with simple ram shins.

Heaight lift for ground clearance on the headlands is excellent.

Heaight lift for ground clearance on the headlands is excellent.

A sturdy platform at the front of the hopper provides easy access for loading.

A sturdy platform at the front of the hopper provides easy access for loading.

A large centrally-mounted distribution head divides the seed out to the 49 runs on the drill.

A large centrally-mounted distribution head divides the seed out to the 49 runs on the drill.

A hydraulically driven fan at the front of the drill uses a heat exchanger, keeps the tractor oil cool and pushes warm, dry air through the hoses.

A hydraulically driven fan at the front of the drill uses a heat exchanger, keeps the tractor oil cool and pushes warm, dry air through the hoses.

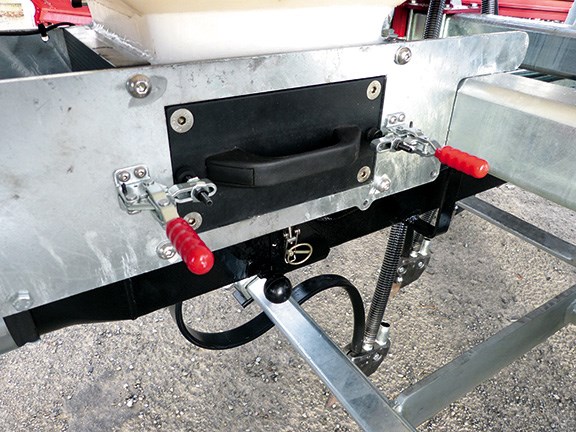

The solid two-point linkage on the drawbar.

The solid two-point linkage on the drawbar.

The 'cassette' slides in under the hopper effortlessly.

The 'cassette' slides in under the hopper effortlessly.

A variety of metering rollers are available for the removable 'cassette'.

A variety of metering rollers are available for the removable 'cassette'.

|

|

'S' shaped spring tine mount onto the box section that is rotating forward. This causes the tines to pull themselves into the ground with little downforce.

|

|

|

The drill and tyre roller following behind both feature impressive contour following, with a simple slotted hole on the folding arms.

|

|

|

|

Heavy-duty phasing rams on the wheels lift all the sections evenly and are used to control the depth of the drill with simple ram shins.

|

|

|

Heaight lift for ground clearance on the headlands is excellent.

|

|

|

A sturdy platform at the front of the hopper provides easy access for loading.

|

|

|

A large centrally-mounted distribution head divides the seed out to the 49 runs on the drill.

|

|

|

A hydraulically driven fan at the front of the drill uses a heat exchanger, keeps the tractor oil cool and pushes warm, dry air through the hoses.

|

|

|

The solid two-point linkage on the drawbar.

|

|

|

The 'cassette' slides in under the hopper effortlessly.

|

|

|

A variety of metering rollers are available for the removable 'cassette'.

|

Brent Lilley heads down to Canterbury to meet Johnny and Paul 'Wal' Crawford and their new Taege six metre air seeder built completely in-house.

This was my first chance to get a close-up, in-depth look at the Taege system and it seemed only right that I throw my two cents in and take everyone back to the school of Taege with an overview of the key features found not only on this drill, but across the range of Taege drills.

Tines

At first glance the tines seem like a fairly simple set-up and that's because they are. An 'S' shaped spring steel tine is mounted on a box section frame, but a closer look at the mounting point of the tine and you'll notice the box section is tilted towards the front, which tilts the tine on a forward angle at the top, allowing the tine to move in an upwards and backwards motion while working.

If you can imagine dragging a fish hook with the tip angled down across the palm of your hand, all it wants to do is dig in and embed itself into your palm. Well, the tine on the Taege drills works in exactly the same way; it naturally wants to pull itself down and into the ground with very little force or weight required.

The other clever part is that it moves the point of the tine further away from vertical with the mounting point, which in turn allows greater freedom for the tine to move up and down with the contours of the ground, or over any obstacles that are struck.

On the new drill there are 49 tines spaced across a six metre working width to give 121mm row spacing. Interestingly this is slightly narrower than nearly every other drill on the market. Tines are staggered over four and a half tine bars which, along with the shuddery nature of the spring tines, help prevent trash build-ups and blockages.

Seed boot

I'll admit that in the past I haven't been the biggest fan of tine drills. In direct drilling situations some can make a bit of a mess. But since seeing the Taege in action I may have to back down on that – the reason lies in what looks like a fairly simple seed boot, but one that has some clever ideas built into it upon closer inspection.

The replaceable tungsten tip at the front is probably the thinnest I've ever seen on any drill. It disturbs a strip that is just wide enough to create a fine tilth to bury the seed in without tearing up the whole paddock.

My first thought was will such a fine tip stand up in harsh conditions? I'm pretty sure the team at Taege takes great delight in seeing the look on people's faces with their demonstation, which involves drilling a section of laneway running through the farm that consists of hard packed river shingle.

The tips, by the way, were absolutely fine and pulled themselves into the shingle, showing no sign of damage afterwards.

Harrows

On the back of the machine are two rows of tine harrows that are set at opposing angles. These tines sweep any loose soil to one side then back to the other, covering the seed and leaving a flat and smooth finish.

The bar that carries the tines is mounted to the drill with a parallel linkage that ensures the harrows always follow flat to the ground. There is an adjustable spring that can be used to vary the down pressure to suit the conditions. The harrows are lifted clear of the ground when the drill is lifted to prevent damage.

Roller

Taege's distinctly unique design uses two rows of tyres that mount to the chassis on an oscillating beam. This not only insures contour following, but also prevents a wave forming to leave a flat and firm surface.

The six metre model is merely an upscale version that features the same folding floating wings like the drill that uses a slotted hole on the folding rams, while achieving a transport width under three metres.

There is no locking device for the wings on the model I saw, but Taege assure me that this is in the pipeline.

Construction

With any folding drill the biggest hurdle to overcome is transferring weight from the central frame to the outer wings to keep the coulters in the ground, while still allowing them to float with contours.

The simplicity of the Taege system stands out once again; because all those 'S' tines are pulling themselves into the ground, no downforce is required. A simple slotted hole at the end of the fold rams gives the wings an impressive amount of travel up and down, from level to following the ground contour.

A clever gravity-operated lock mechanism also prevents the ram from sliding in the slotted hole when unfolding the wings. Two wheels under the centre section are used for transport and, along with a further wheel on the outside of each wing, control the height of the drill, while phasing rams on each wheel ensure that all three sections lift at the same time on the headlands.

The big difference between the standard cultivator and the drill is the draw bar frame, which bolts on the front.

On the drill it's longer and stronger to accommodate the seed hopper and the air setup. They have also done away with the towing eye in favour of a hefty two point linkage hitch to the tractor, which allows for independent contour following, tighter headland turns and the ability to level the drill.

Fan and hopper

The hopper is a tough moulded plastic unit with an impressive 1400-litre capacity, a wide opening at the top and an access platform at the front. It's simple to load too, whether from 25kg or half-tonne bags. A canvas cover with a steel frame folds to one side for easy access and secures with bungees to ensure moisture stays out.

As yet there is no grate inside the hopper, which could lead to problems. Up front a hydraulically driven fan is fitted with a heat exchanger. Fan speed can be adjusted through the oil rate from the tractor and is displayed on the monitor in the cab.

Metering

After having recently tested a number of drills that all featured the same well-known reliable metering system (which remains a good system), it was a breath of fresh air to see Taege once again doing something a little different.

Its metering units have been developed in-house and use a plastic block or 'cassette', which fits snugly under the base of the hopper and locks itself to the shaft from the seed drive motor. It is held in place with two sturdy retaining clips. Inside the cassette are the metering rollers, which can be chosen from a range that includes the tried and tested Taege sponges along fluted and notched plastic rollers.

The simplistic beauty of this idea is that you can have as many cassettes set up with different rollers as you need.

The ability to completely remove the metering system also helps when cleaning out the drill and preventing damage when the drill is not in use. A simple addition of a slide shutter between the hopper and the metering unit would enable the metering cassette to be removed while the hopper has seed in it.

Control and calibration

Electronic metering is where it's at now in my opinion. Anyone still calibrating a drill by turning a handle then working out on the back of a cigarette packet is in the dark ages.

Fortunately for Taege the reliable electronic drive motor and control box they developed for their smaller gravity box drills was easily transplanted to the new air seeder. Although the box might not be as flashy as some, it's straightforward to use.

A small screen displays the important info and membrane panel buttons are easy to use. Handy features include the ability to switch between two pre-set rates or bump the rate up or down on the move. Different seed types and jobs can be stored in the memory.

Calibration of the drill is simple: without the fan running, open a hatch under the metering unit, hold the prime button on the monitor to run some seed through the rollers, then slide a container under the metering unit and press the calibration button. This will meter out a set amount of seed, weigh it then enter the amount into the monitor.

Taege realises that people never get around to reading encyclopaedia-sized manuals, so instead supply a single A4 sized laminated card that covers all you need to know.

The verdict

When it comes to the six metre machine, I was impressed with its simplicity and cost when compared with other machines this wide. The fact that they have largely managed to make it happen by combining components and design features from other machines in the wider range should give prospective owners confidence in a well-proven concept.

Pros

- Very simple, robust design

- Tines pull themselves into the ground with no down force required

- 'Cassette'-style metering system means it's very easy to change rollers

- Large 1400-litre hopper capacity

Cons

- As yet no locking mechanism for the wings on the drill or the roller (although I'm told this is being worked on)

- No grate in the seed hopper

- A slide on the bottom of the hopper would make it possible to remove the metering unit with seed in the hopper

For the latest reviews of farm machinery, subscribe to Farm Trader magazine here.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpg)

.jpg)

.jpg)