Duncan Ag TFD drill review

|

|

|

|

|

|

|

|

A third-generation Clough family business, Duncan Ag is one of the stalwarts of agricultural machinery in New Zealand.

Over the years I have test-driven much of the range, but on this visit to Timaru I wanted to check out the Duncan Ag TFD drill – and it was well worth the trip.

Duncan Ag recently took its range of drills on the road in Canterbury to show off the latest models. After a false start with an early morning missed flight, I managed to catch up with the Duncan Ag team on a dairy farm north of Timaru.

Although it was a great opportunity to check out four of its drills, I have to be honest and say it was the Duncan TFD drill I was most interested to see for myself.

Construction

It’s great to see a machine designed specifically for farmers that has been kept simple, and yet is robust. At the front, a towing eye makes it quick and easy to hitch up. There is also the fact that the drawbar pulls low off the frame of the drill, preventing the drill from pulling forward over itself.

Two 500-litre steel boxes are mounted at a carefully set height to ensure gravity delivers the seed to the coulters and a single steel lid opens to give access to both boxes. These also feature agitators to prevent bridging. A grate in the hopper would be handy to prevent seed bag tags or other objects getting into the metering system.

The two wheels are spaced out wide on the frame for stability, with rams lifting the frame up on the wheels for turning and transport. The depth of the coulters is also controlled on these rams, with a steel collar similar to a shim, which can be adjusted up or down a threaded section of the ram spear to alter its length of travel.

At the back of the drill, a wide platform with hand rails and steps gives good access to the bins or can carry a few extra bags of seed. The machine tested was also equipped with a set of optional tine harrows on the back to cover the seed, along with a rear draw bar to make it easy for a roller to finish the job nicely.

Coulters

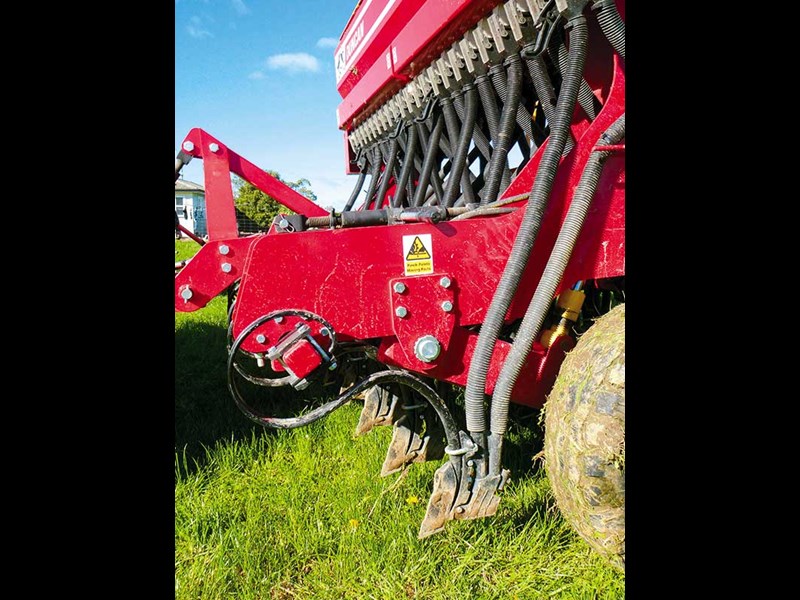

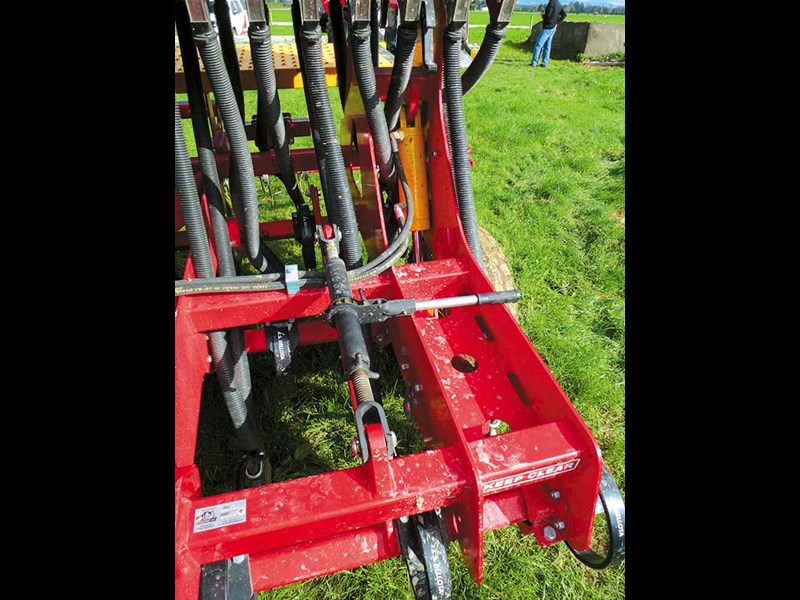

The key difference of this drill over anything Duncan Ag has built in the past lies in the S-shape tines which carry the points and the seed boots. They are high quality European Bellota spring steel tines which are incredibly flexible yet very strong.

I almost feel like I should be whispering here so as not to give the secret away, but the key to its success lies in the box section beams that the S-tines are fixed to. They are mounted to the drill frame in nylon bushings which allow the beams to be rotated to the front or back with a top-link style screw adjuster.

This changes the angle at which the drill points strike the ground, rotating the beam towards the front of the machine so the angle of the points becomes more aggressive, giving them more bite – ideal for direct drilling where you want them to pull into the ground, or rotate the beam to the rear on softer cultivated ground for less disturbance.

In practice, this set-up works really well and only a small amount of adjustment can make quite the difference in the effectiveness of the points. The lack of a scale guide on the adjuster can make it difficult to put it back to where you started, but I’m told this is in the pipeline and will most likely be on future machines.

Points and boots

The cast points bolted to the front of the coulter tine use a very thin tip to cut a slot for the seed without ripping up half the paddock. Also as the tip itself is tungsten, it is very resistant to wear and can stand up to use in the harshest conditions.

The shuddery nature of the tines and points serves two very important purposes. Firstly, the movement of the tip in the soil creates tilth (loose soil), one of the necessities for a successful strike of seed. Secondly, it keeps the coulters free of trash which prevents blockages.

Behind the point follows the cast iron seed boot. Although the machine tested was only a twin box drill, it has three separate shoots to future proof it if you ever decide to add small seed or slug bait boxes. The well-thought-out design uses side walls to hold the slot open for the seed and a large open bottom which will resist clogging in unfavourable conditions.

Control and calibration

Up in the cab I found a familiar RDS control monitor which Duncan Ag uses across its range of seed drills. Featuring a reasonable-sized mono-colour display, along with easy to follow buttons which correspond with icons and tabs on the screen to access the features of the drill.

This monitor can control up to four separate boxes which are selected on the screen. They can be turned on/off and rates can be set or adjusted on the move, along with all the other features you would expect to find. A single set of hydraulic remotes is required to lift the drill up out of work and a sensor detects the height to start/stop the seed and the monitor beeps to let the operator know.

Plastic peg toothed wheel metering units are shaft-driven from electronic motors with the ground speed measured by radar on the front of the drill, which makes calibration particularly easy. The clever part when it comes to calibration is that there are around 20 different seed/fert types with preset rates stored in the memory. For example, if you select grass, it has a preset rate of 25kg.

To calibrate, set the seed collection trays in place, open the flap to direct seed into the trays, then simply press the run button of the side of the drill to run seed through. Press the button again to stop then weigh the seed. The monitor will have already measured the rotation of the metering units and calculated the weight.

When you enter the actual weight you have measured, it will show the percentage of error between them and ask you to confirm your weight. This provides a failsafe mechanism to ensure mistakes aren’t made when calibrating the drill. Once it is all confirmed, the rate can be simply adjusted on the monitor to the desired amount per hectare and you are good to go.

The verdict

For a machine labelled by Duncan Ag as ‘The Ideal Farmers Drill’ or TFD, it is great to see that they have stuck with the keep it simple school of thought. Most farmers want a simple reliable drill that they can back in, whack the drawbar pin in and be off drilling, then fire it back in the shed until next time. The Duncan Ag TFD definitely caters for this.

Overall, the Duncan Ag TFD is a well-thought-out and well-built drill that will appeal to many – and with a competitive price tag, it provides a really economical option for farmers who want to do their own drilling.

Pros

- Robust flexible S-tine provides great contour following.

- Rotating mounting beams allows the adjustment of the angle of the points to suit the conditions.

- Electronically driven seed metering unit with ground radar for speed measurement.

- Easy to use control monitor with a clever built in fail safe measures when calibrating.

- Seed boot with three shoots to future proof the drill for the addition of further boxes.

Cons

- No scale on tine angle or height adjustment.

- A grate in the seed hoppers would be handy to prevent foreign objects getting into the metering system.

Read the full review in issue #218 of Farm Trader magazine. Subscribe here.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpeg)

.jpg)