Test: Siloking Duo 3022

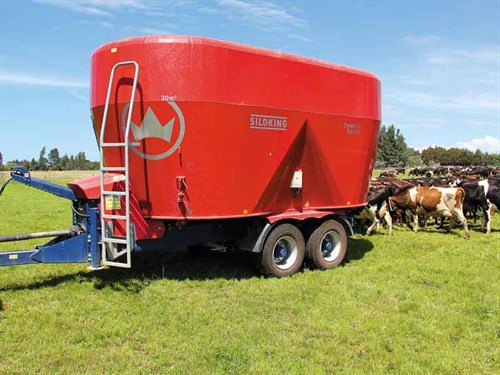

Farm Trader checks out the Siloking Duo 3022 being used on a dairy farm in South Canterbury

Farmers around the country don’t seem to be able to catch a break at the moment. As well as grappling with the earliest big dry many can remember for generations, we’ve also had to contend with one of the wettest starts to the season in decades.

Taranaki dairy farmers are drying their herds off completely, meaning seven months dry with little to no income. Sheep and cattle farmers are unloading cattle to take the pressure off. Regardless of the type of farming, the financial pressure is likely to be crippling for many.

How is this relevant to a piece of equipment? Well, I’m a big believer that you need to eliminate risk to your business and that often you need to spend money to make money.

Firstly, risk; how do you eliminate this? In farming, there are many unknown variables. This is where making sure you have the right piece of machinery for the right job comes into play; in this case, the Siloking Duo 3022.

There are two major things in farming that you have no control over, and they make a massive difference to the bottom line. The first is payout, and in the case of sheep/beef/deer, schedule.

Essentially, you have no control over this and can manage your business as efficiently as possible to make a margin based on your projected income. But if the income changes (i.e. a payout drop or change to schedule), you have no control over this.

The second major risk factor is climate. Again, you have no control over this but can vary the effect it has on your business and the impact this will have on your bottom line. This is where the spending money to make money comes into it. Now before I explain my theory, my disclaimer is: I am not encouraging everybody to go to the extremes of System 5 (imported feed used all year, throughout lactation and for dry cows).

Enter a mixer wagon into the system (not a free stall barn, concrete silage bunkers, extra staff, and additional tractors and telehandlers); just the wagon. This gives you the flexibility, particularly when it is dry, (don’t take them in the paddock when it is wet for sanity’s sake) to feed stock in a sacrifice paddock and give them a balanced diet, and more importantly, minerals to ensure animal health issues such as facial eczema or ryegrass staggers don’t complicate an already stressful situation.

This then leads on to the spending money to make money argument. In drought situations, the rain will come eventually, so you need to be able to hold on until it comes. A mixer over a silage wagon will allow you to feed gut filling feeds such as straw and lower quality balage, with other feeds, which may be higher in specific component such as protein.

This gives a balanced ration and potentially means less feed eaten (total DM), but because the less palatable feeds i.e. straw are chopped and blended rather than fed directly in the paddock, overall utilisation will be up. Your stock will have the ‘full stomach’ feeling, which will make them more content. Additionally, you can add water to the ration to reduce demand on troughs and weight loss due to heat stress.

The test

Ikon Machinery is the importer of Siloking mixer wagons and is based in Geraldine, South Canterbury. The family-owned and operated business specialises in high-quality machinery, focusing on brands that are ‘iconic’ in their markets. Each brand represented specialises in its field and in making their machines by the mark of quality not quantity.

Dean Campbell, from Campbell Holdings, recognised that the Siloking Duo 3022 would suit his 1300-cow operation in Geraldine, South Canterbury. Impressed by the features, benefits, and specification, he bought this machine two years ago.

The Siloking is well-made with quality German components. Everything apart from the axles is built in-house. It’s the little things that add up to create a high-quality product, and this is a well-thought-out, high-performing machine offered in many variants to suit different feeding situations, bin capacities, and configurations.

Tub and augers

Speaking of configurations, the trailed premium range (which includes the 3022 machine we tested) gives the added benefit of large capacity but with a compact design. The Siloking trailed 3022 is the largest in the tandem axle configuration with a capacity of 30m3.

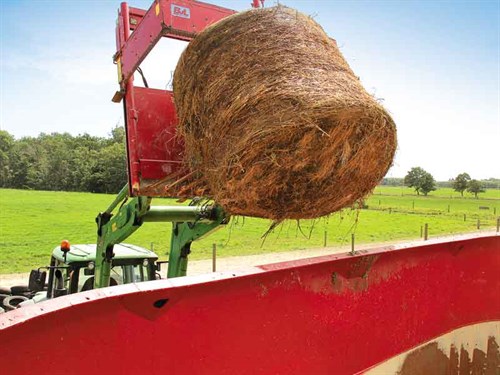

It is quite tall, meaning that for some situations, it won’t suit the existing loading machine. However, the top ring is strengthened and has a lip inward, which allows feed to be kicked well inside the mixing bowl and stops it overflowing, which can be an issue with very fibrous mixes.

The ratio between hopper height width and the appropriate size auger is the heart of the Siloking mixing philosophy. The augers are designed in a way that it’s not just extensions added to the top of the bin and expecting the augers to give a consistent mix (which simply doesn’t work).

As the bin height goes up, the auger flighting also goes up. This allows the geometry of the hopper and the auger to work together to give shorter mixing time and better feed quality.

The hopper recess, which is visible from the outside, gives the feed a figure 8 pattern inside the mixing bowl, which combined with the vertical mixing process gives consistent feed blending.

Silo Knox is a hard-wearing solid stainless alloy, which is an added option to this machine and significantly extends service life. It is coated on the auger flighting and the hopper floor (6mm) and walls (3mm).

The turbo auger design has an off-centred auger flight, which intensively mixes the feed even at low speed. This gives short mixing times without damaging the consistency of individual feeds. The scraper bars along the bottom help flip the material up off the bottom, back up the augers, and distribute it evenly throughout the machine.

Undercarriage

The sprung tandem axle with rear steering gives the machine a short turning circle for the capacity, where 30m3 in many other brands is triple-axle material.

The grunty chassis gives the ideal platform for the high-capacity load cells, which are nestled in cast steel for both strength and accuracy.

In terms of the driveline itself, the planetary gearboxes and the main gearbox are well protected and secured in the heart of the chassis. The main gearbox has a separate shaft to each of the augers to reduce stress on the driveline.

Discharge

Different feeding options are available. This test machine had the standard side conveyor with a nifty hinging system, which folds down and under the tub to reduce wastage but allows feed to be propelled into feed troughs. Front cross conveyors, conveyor extensions, smaller bedding belts, or simply a discharge flap at either the front or rear are available.

Scales and monitor

One of the major features of the Siloking is the wireless control and weighing system, which simply plugs into a D plug to power up the system. The wireless monitor in both the loader tractor and the feeder tractor can then talk to each other, giving the updated weight as loading is carried out. Another clever feature of this monitor system is feed management. You can change the mix for the cow numbers, the total amount or the recipe, etc., so farm staff can simply load what the monitor tells them.

As this was the first machine of its kind to arrive into New Zealand, the only real upgrade that has changed since it arrived is the new terminal, which is colour screen and is intuitive to use, with mainly buttons up each side of the screen for a logical layout.

All the electronic equipment in terms of the control box, battery, etc. are all well tucked away out of the weather and dust, as well as an isolating switch so when the machine is not in use, you can prevent any unwanted faults.

Some will like the electric over hydraulic control where everything is push button from conveyor speed to discharge, hydraulic jack stand, or the variable speed two-speed gearbox. Some people may prefer a more mechanical set-up, which again is an option where it can be run through the tractor. However, the wireless scales and monitor, particularly in the loader tractor, are a good feature.

The wireless scales and hydraulic jack stand make it ideal for a one-man operation where loading and feeding with the same tractor can be easily achieved. Having said that, with the 30m3 capacity, you would want to be very careful about the order in which you loaded. If you wish to pursue this option, there is a clever soft starter clutch option. This is a hydraulic clutch located between the planetary gearboxes.

Starting the PTO with the clutch disengaged will just do the first auger. Once that’s been mixing for a little bit, you then engage the clutch and the second auger will start. This reduces tractor power requirements by 50% before you have even added the cost of the additional equipment in a conventional set up.

Verdict

The auger height comparative to the bin height is a good feature and is something that not all manufacturers offer. The steering axle and large bin capacity make the machine very manoeuvrable for its capacity.

Loading height is the only obvious downside of the machine, where it is almost telehandler material, but there is an obvious trade-off between manoeuvrability and height. Build quality is high, feed consistency was very good, and the in-cab controller was a nice feature.

This level of technology is something that won’t suit everybody, but the more mechanical set-up can be spec’d. Overall, an impressive build quality and given they only build mixers, it’s the little things that make the difference.

Pluses

- Auger height is proportional to bin height to ensure consistent mixing

- Siloking only build mixer wagons. Almost all components are made in-house with high levels of build quality.

- Large range of configurations

- Oil reservoirs are easy to see on the outside of the machine

- Two in-cab controllers

- All functions are carried out on the monitor wirelessly from in the cab; two-speed gearbox included

- Given the capacity, the 3022 was highly manoeuvrable

- Main gearbox is well protected and secured

- Each auger is driven from its own shaft from the gearbox reducing the stress on the drive line

Minuses

- Loading height is high (lower models available)

- The electric over hydraulic controls are very good but does add a level of sophistication some may not like (mechanical options available)

Read more machinery tests and reviews on Farm Trader.

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook