Test: Brevi Mekfold 300

Hydraulic packer roller depth adjustment

Hydraulic packer roller depth adjustment

Hydraulic lock for beds when in transport

Hydraulic lock for beds when in transport

Individual adjustment of scrappers on the packer roller

Individual adjustment of scrappers on the packer roller

The five-metre machine has a 300hp central gearbox and runs 170hp side gearboxes

The five-metre machine has a 300hp central gearbox and runs 170hp side gearboxes

A central tine between the two beds and adjustable side wings ensure a smooth finish

A central tine between the two beds and adjustable side wings ensure a smooth finish

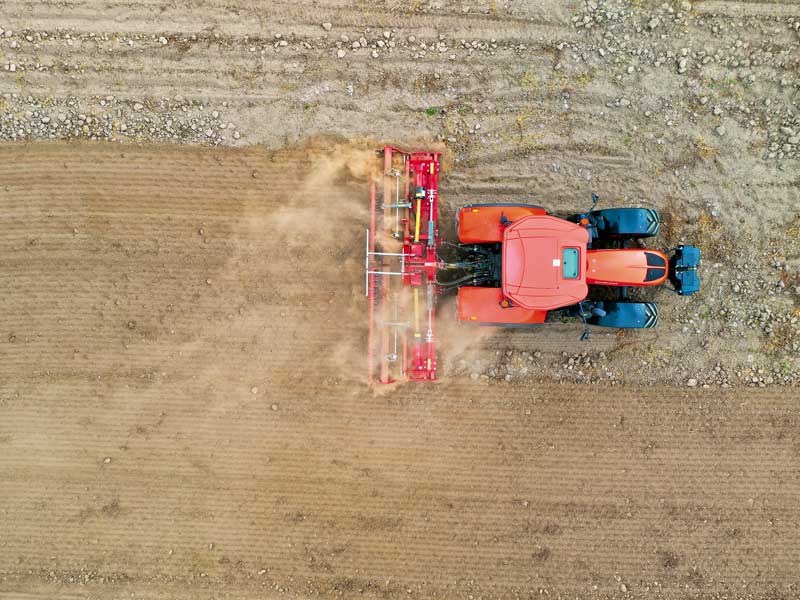

High rotation speed tines chew through the dry soil conditions

High rotation speed tines chew through the dry soil conditions

Levelling boards attached to rear roller for simple adjustment

Levelling boards attached to rear roller for simple adjustment

The power harrowed result compared to rough ground on the right waiting to be done

The power harrowed result compared to rough ground on the right waiting to be done

|

|

|

Hydraulic packer roller depth adjustment

|

|

|

Hydraulic lock for beds when in transport

|

|

|

Individual adjustment of scrappers on the packer roller

|

|

|

The five-metre machine has a 300hp central gearbox and runs 170hp side gearboxes

|

|

|

A central tine between the two beds and adjustable side wings ensure a smooth finish

|

|

|

High rotation speed tines chew through the dry soil conditions

|

|

|

Levelling boards attached to rear roller for simple adjustment

|

|

|

The power harrowed result compared to rough ground on the right waiting to be done

|

When it comes to choosing the machine for the job, farmers and contractors are spoilt for choice, so Farm Trader set out to test-drive one of the hot contenders in the market – the Breviglieri Mekfold 300

To put the machinery through some testing conditions, we headed north to Dargaville where Jono Leigh from Norwood also invited us to test the flagship of the Kubota range, the M7-171, hooked up to the Breviglieri (Brevi) Mekfold 300 five-metre power harrow.

Dargaville is renowned as a kumara growing area, so rotary hoes are a common sight, crawling through paddocks to achieve the fine, lump-free soil bed ideal for growing and harvesting.

Crop rotation for kumara is often either being left fallow between planting or being sown in pasture for 12 months to help build up organic matter before going back into kumara.

While I arrived to test the five-metre Brevi power harrow, the season’s kumara had just been harvested. The post-harvest pasture condition featured plenty of large rock solid lumps of soil and ruts, where machinery had been through the paddock during the harvesting process.

|

|

The five-metre Brevi is easy to set up

|

Given that we were only hooked on to the 170hp Kubota (the central gearbox is rated to 300hp, side gearboxes 170hp), I was impressed at the results when we lined the harrows up to tackle some of the worst of the paddock – head size lumps of baked hard soil and ruts. The CVT transmission slowed the tractor down to give the Brevi time to do its job.

I would suggest opting for a bit more horsepower if you’re working on steeper or more undulating terrain. Also, the 3200kg weight of the five-metre power harrow may feel more stable with the weight of a larger horsepower six-cylinder tractor and extra weight on the front end.

Brevi Mekfold 300 features

|

|

Packer and cage roller options can be switched for various ground conditions

|

The ease of set up is a key feature of the Brevi Mekfold power harrow. The hydraulic lock (when in transport) removes the need for a manual string unlocking system.

Even with this, only three hydraulic remotes are required: the second to fold the two beds out horizontal for work, and the final remote for adjustment of the packer roller.

There are a number of packer and cage roller options, which can be switched depending on ground conditions. The 450mm standard roller seemed to work fine for what we were doing on test day. Another feature I like is the fact the manually adjustable levelling boards are attached to the rear roller.

This makes it particularly easy to make fine adjustments without the need to stop and change pin settings.

To minimise the chance of leaving a ridge of soil between the two beds, Brevilgeri has fit a single tine that feeds into the tines on either side. The cam clutch on the PTO shaft is well placed to protect the tractor gearbox against damage in case of striking something hiding beneath the surface. Making use of tractor headland management settings to engage or disengage the PTO as you lift on the headland turns will also minimise the chance of drive shaft damage.

Construction and design

|

|

Visual gauge for correct adjustment of levelling boards

|

Designing PTO-driven cultivation implements since 1949, Brevi has had plenty of time to fine-tune its designs. Some of the most important features are hidden from sight but are key to the reliability and longevity of these machines. Using high horsepower-rated gearboxes helps keep the noise and temperature down.

When folded out for work, the beds sit level to prevent potential binding of the cv shaft joints. Through the bed of the power harrow, larger than required gears drive each module. The reason for this is for both low noise operation and decreased temperature while operating, negating the need to add an extra oil cooler at additional expense.

Aside from changing tines or gearbox oils, the other job that may be required is seals/bearings in a module. Removing the top cap, an individual module should be out and back together in under a couple of hours.

Kitted up with overwidth panels and lights for transport operations, the only small negative I could find with this machine is the need to remember to remove these before you start work and to collect them afterwards.

Another option to make your power harrow more versatile is to mount an air seeder, so you can have the seed in the ground and one less trip around the paddock, for not a lot of extra cost. A tow hitch on the back also provides fresh options if you want extra soil consolidation and firmer seed. This could also be handy for towing a vehicle if you have a big job away from the home base.

About Brevi

|

|

Heavy box section steel is used in the frame construction

|

Brevi is an Italian machinery manufacturer. Founded in 1949 by Oreste Breviglieri, who obviously possessed the Italian equivalent of Kiwi ingenuity, having a hand in developing the concept of soil engaging PTO-driven equipment for cultivation. At the time this was groundbreaking (classic dad joke) and a big step forward in the mechanisation of farming over traditional methods.

Over the years, Brevi has continued its focus on building high-quality machines, with many international patents awarded for design and innovation.

Today, the company produces a range of soil preparation tools, rotary tillers, inter-row tillers, power harrows, flail mowers, and mulchers. Their range is available through Norwood branches around New Zealand. Depending on your workload – whether lifestyle, horticultural, or large farm or contractor – there’s a machine to suit most situations. The Mekfold is available in one-metre to seven-metre options, with a nine-metre machine underway.

Verdict

|

|

Narrow transport width for operation on public roads, lanes and gateways

|

I was impressed by the Brevi Mekfold 300 five-metre power harrow, particularly the ease of adjustment of the roller and levelling boards with hydraulic function, which also locks the two beds when in transport.

With years developing PTO-driven tillage equipment, refinements over the years sees Brevi produce a quality product with plenty of smart design features.

Brevi Mekfold 300 specifications

| Working width | 5m |

| Transport width | 2.59m |

| Tare weight | 3200kg |

| HP requirement | 160–230hp |

| PTO speed | 1000rpm |

| Options |

500mm roller, cage/crumbler rollers, quick-change blades, attachment for mounting |

Pluses

- Hydraulic transport lock

- Hydraulic roller depth adjustment with levelling boards with manual adjustment

- 300hp central gearbox, 170hp rated gearboxes either side

- Large gears used to minimise heating of gearbox oil

Minuses

- Fixed over width panels and lights

Watch the Brevi Mekfold 300 in action

Find more power harrows for sale in NZ

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpg)

.jpg)