Cover story: Kennan MechFiber345

Keeping stock supported with high-quality nutrition year-round is of crucial importance for effective farm management. The Keenan MechFiber 345 is proving a game-changer for a Tokoroa couple.

.jpg)

This month we caught up with sharemikers Casey and Samantha Hartley in their first season on a new farm with a new Keenan MechFiber345 (with the InTouch system), which, along with other management factors has them on track for record

cow production.

Test time

Purchased at the end of the 21/22 season in anticipation of starting a new job this season, the Keenan MechFiber plays an important role in their farm planning and management. Moving to a 260-cow, system 3 farm and making use of a feed pad meant that after considering a variety of options, a new Keenan MechFiber345 ticked the boxes for all of their requirements.

Sitting comfortably in the mid-capacity size at 16 cubic meters, the Keenan MechFiber345 is similar in overall size to the 320 (smaller) and 365 (larger) models. Although the machine specs say the unit can feed 65–100 dairy cows, this is more relevant for overseas markets and is based on one load per 24 hours on a full TMR (total mixed ration) system.

One of the few differences between the 345 and the larger 365 model is the addition of a rear steering axle on the larger model (and capacity obviously). For a larger farm with more stock and a tight feed pad, the rear axle could come in handy.

|

|

Loading height proves no problem with common 100hp FEL tractors used on farm

|

However, the 345 is perfectly suited to the requirements of Casey and Samantha. It’s available in either a single- or twin-axle set-up; the Hartley’s opted for the twin axle, which is more manoeuvrable for the feed pad (tighter turning circle than single axle).

Casey runs the mixer on his 100hp New Holland, which is more than adequate, and, in fact, you can get away with as little as 90hp on the Keenan 345 (although, I reckon this would probably be best-suited to operating on pretty flat ground).

The unit does also come with hydraulic brakes to stop the weight of the wagon and load pushing a smaller tractor. The Tokoroa farm Casey and Samantha sharemilk on is well set up, with a concrete feed pad and bins to save wastage of the mixed feed.

Casey has also recently finished concreting the loading area where the supplement is stored and mixed. He also has tanks here for both water and molasses (an important part of the Harley’s mix) along with covered storage for his PKE blend, bunkers for bulk maize and silage, room for bale storage, and a small dry shed to store minerals. Part of utilising the Keenan features and technology has involved sourcing professional advice from Keenan nutritionist Alejandra Vergara and Keenan brand manager Ian Good, ensuring maximum efficiencies.

|

|

Dual or single axle options are available

|

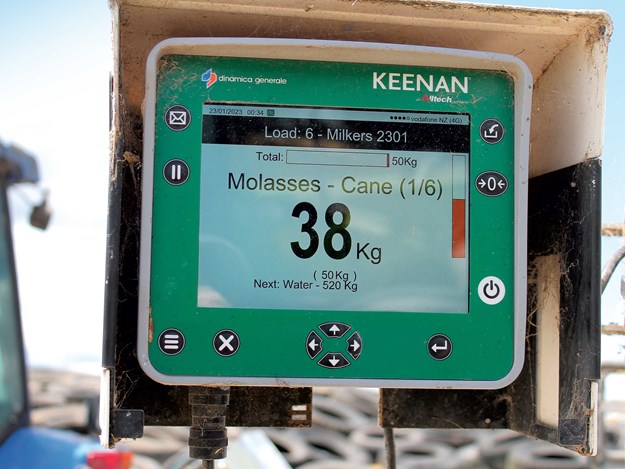

When it comes to machinery design, Keenan has a well-earned reputation for quality and innovation. To achieve the perfect consistency and accuracy of mix, the mixing chamber sits on four load cells connected to the InTouch controller, which counts down the volume required of each ingredient.

The addition of the InTouch system allows for easy checking of mixes on the controller. It also means that even if different staff members are making the mix and perhaps not being accurate with specific inputs, the controller will highlight this and show the mix recipe as percentage over and under, allowing an easy and important correction. Diets can be sent wirelessly to the controller by

the nutritionist.

Any number of mixes can be stored in the InTouch controller, so this conveniently caters for adjustments depending on what ingredients you have available and what the nutritional requirements of the animals may be at certain times of the year (e.g. growing, pregnant, or dry). The number of animals to be fed is also easily adjusted on the controller or through a simple phone app, which comes in handy on a dairy farm in spring, where herd numbers may change daily. Another convenient feature of the phone app is being able to see the mix progress in real-time on your phone.

|

|

Bale blend tines for handling baleage

|

The day I was on farm with Casey, he made one mix of around 2500kg for his 260 cows. At this time of year, they are fed once a day, as he has good grass in the paddock. If need be, he could easily do another mix in the morning if the cows needed extra kilogrammes DM or his quantity and quality of grass available was affected by weather, etc. With how he operates his stock management, Casey is more than content with the size of the MechFiber345. Without the mixer, he would be doing multiple wagon loads of silage and maize daily, taking up a considerable amount of additional time and effort.

InTouch system

The Keenan InTouch system was introduced in 2009 by the Irish company and continues to evolve and impress. The feed management tool is user-friendly, durable, and simple to use. While some farms may be happy enough to work out their own feed regimes, utilising accurate data monitoring offers peace of mind around accuracy and efficiency. Add to that access to the Keenan nutritionist and it offers a step up in optimising feed inputs and animal production.

|

|

The Keenan InTouch system showing weight of product in mix

|

Along with the reliability of purchasing a reputable new Keenan machine, you also receive 12 months of support and advice from the experienced Keenan team around its InTouch system. Following this initial period, there is a fee for this continued service, but in my opinion, it’s money well spent when you take into consideration the expense of feed wastage.

Mixes and mixers

The Keenan paddle mixer can mix anything you could put through a slightly more common tub mixer. One difference with the Keenan is that if you want to feed bales, the addition of baler handler tines help the machine process the bales. Breaking them up before

loading the mixer also helps speed up the mixing process.

The Keenan MechFiber mixer also differs from standard tub mixers where cutting knives are mounted on the mixing augers. Keenan mounts them through the belly of the machine to cut the fodder without damaging it, achieving a cutting, tumbling mixing action.

|

|

Mix is neatly and easily fed into feed pad bins

|

On this farm, they use water and molasses as a base, with the aim of having a finished mix at 45% dry matter. This along with the easy mixing action allows cutting to the correct length without destroying the fodder. This, in turn, helps with optimal digestion and feed conversion. Differences between fine chop silage and loader wagon or baleage can affect the time (mixer rotations) needed to achieve the desired mix consistency.

On farm

The benefits of new machinery usually come in the form of greater productivity – getting the same jobs done in less time. During the Keenan MechFiber345’s first year of operation, Casey has found plenty of positives for his business.

Through calving to days with the worst weather, he hasn’t had issues with milk fever and associated lost production for the season. Having minerals distributed in the correct measure to animals through the feed mix also saves a separate and time-consuming job of dusting paddocks. It also avoids waste that definitely happens using other systems, whereas with the mixer wagon and InTouch system accuracy is assured.

|

|

Happy cows = happy farmers

|

The controller gives the correct amount of each input, saving dollars on overfeeding by even a small percentage, and these days, every dollar counts. The Keenan mixer combines what could be up to three separate jobs: feeding concentrate feeds in the shed, grass silage in the paddock, and maize on the feed pad. Another benefit is being easily able to adjust the mix to cater for changing animal numbers in different herds, using the InTouch controller and phone app. This can even be done from home before feed-out time, as the unit automatically updates when the monitor is turned back on. There’s nothing quite like the peace of mind that knowing your herd is getting the minerals it needs on a daily basis.

Construction

Keenan has been making horizontal paddle mixers for many years and has proven its expertise not just in Ireland but around the globe.

Longevity and reliability go hand in hand with a Keenan machine. Maintenance is kept straightforward with a bank of grease nipples at the front of the machine taking care of all the front bearings. An oil bath chain drive has now been fitted to smaller machines, whereas previously this was used on the larger machines only. This helps keep chains lubricated and minimises wear. Keenan service agents are located around the country, and for older machines, there is also the useful ability to rebuild those dependable frames, even relining the mixer if necessary.

|

|

Magnets on the feed out arm minimise the chance of losing stock to metal disease

|

Action Agriculture

One of the newer machinery dealers on the block in the Waikato, Action Agriculture took over distribution of Keenan in New Zealand about 18 months ago from JK Engineering (who continues as a service agent for the upper North Island).

Along with the Keenan machines, Action Agriculture also offers the German-manufactured Krone brand of grass machinery throughout southern Waikato and south into the King Country. Rounding out the range of equipment available is the Hardi range of sprayers. The family-owned business is proudly based in Kihikihi, with a strong focus on harvest and feed-related agricultural equipment.

Summary

The Keenan brand of mixer wagons have always been a quality product. The MechFiber horizontal paddle mixers are built to carry on this mantra, offering reliable service day after day, efficiently keeping animals fed on farms.

Keenan MechFiber345 Specifications

| Controls | Hydraulic |

| Monitor | InTouch, machine mounted |

| Mixing system | Horizontal, 6 paddle |

| Feed out system | Left side discharge auger (other options) |

| Axles | 1–2 axles |

| Height | With baleblend 3, 119mm |

| Width | With baleblend 2, 768mm |

| Length | 6250mm |

| Payload | 6000kg |

| Mix capacity | 16m |

| Min Hp required | 90hp |

| Importer/distributor | Action Agriculture |

PROS

- Clear view monitor and the ability to view through the phone app is very handy

- Low maintenance with auto chain oiler and easy access bank of grease nipples

- Good cleanout of mix with horizontal beaters for accurate feed allocation

- Nutritional advice/support available through InTouch monitor and Keenan

- Low hp required to operate

- Long service life, can reline and keep on using for many years

CONS

- A solar panel or sleep mode for the monitor after a set time would save the possibility of a flat battery just in case you forget to turn it off

Find new and used farm machinery for sale in NZ

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.png)

.png)