Cover Story: New Holland FR780 Forage Cruiser

New Holland's FR780 Forage Cruiser incorporates impressive technology designed to ensure crops are harvested as efficiently and economically as possible

The modern forage harvester is a complicated piece of machinery, representing cutting-edge technology and design.

The mechanics and horsepower involved in cutting a two-metre-tall crop and chopping it up into 10mm pieces has always fascinated me, and I still get a kick out of operating these complex machines.

The New Holland FR model of forage harvesters was released 10 years ago to replace the FX models. The FR range represented a huge leap forward for the company, which has continued to upgrade and refine the machine.

We took some time during the maize season in Waikato to see the New Holland FR780 Forage Cruiser in action and check out exactly what it brings to the table along with the upgrades that are part of this latest release.

This monster machine has a maximum output of 775hp, which is achieved between 1700 and1900rpm. While power and performance are key, it is also cleverly designed to maximise efficiency, particularly fuel efficiency.

Feeding

Feed rollers serve two important purposes. Firstly, they compress the crop into a uniform mat to ensure precise cutting. Secondly, they feed the crop in at an even speed to produce uniform chop length.

New Holland boasts the widest feed rollers and chopping cylinder on the market, which means material is fed to the cutting cylinder in a wider, thinner mat. Along with the HydroLOC drive system, this produces a precise uniform feeding and, therefore, precise length of chop.

The HydroLOC system uses a hydraulic motor to drive the gearbox on the feed rollers, powering them separately of the cutting cylinder. This drive set-up means the speed of the feed rollers and length of chop is infinitely variable from the cab.

Double Feeder Drive – a standard feature on the FR Forage Cruiser range – uses an additional hydraulic drive motor to drive the header. This increases the power to the header and prevents it from slowing the feed rollers down in heavy crops.

It also allows the speed of the header and the speed of the feed rollers (chop length) to be varied independently and infinitely. In my past experience of driving forage harvesters, this is something that is well worthwhile, particularly with heavy crops such as maize.

Metal and rock detection

With machines of this value, metal detectors are a must to prevent damage. The problem of detecting rogue metal in the crop usually falls on the trailer driver beside the machine. However, New Holland has come up with some clever ideas to make this process as easy as possible.

The feed rollers are divided into six separate detection zones, and the MetaLoc system brings the feed rollers to a halt in 0.003 seconds from detection (with the help of the HydroLoc gearbox). The in-cab monitor then displays to the operator which section the detection is in, making it easier to find the metal across the wider width.

To show the trailer driver where the metal is on the feed rollers, the indicators on the machine are set up to flash the correct number of times (from one to six) to correspond to the zone where the metal is. In my experience, I reckon it’s easier and quicker to point out where the metal is located, but there’s no denying the convenience of this system.

New on these models is a rock alert system that monitors the up and down movement of the feed rollers. If the machine senses a large or sudden movement in the feed rollers, they stop so the foreign object can be removed. Like the metal detector, sensitivity can be adjusted to suit the conditions.

Chopping cylinder

The cutting cylinder is definitely the business end of the machine. Spinning at more than 1000rpm, it can chew through a serious amount of material – and fast. Not only does the New Holland FR780 have the widest chopping cylinder on the market at 884mm wide, but the whole feed channel from the feed rollers through the cutting cylinder and processer to the accelerator is also widened to enable the machine to process a larger quantity of material.

Each knife is attached to the cylinder with five bolts for safety and they are arranged in a chevron pattern for a smooth, efficient scissor-like cutting action against the shear bar. There are several options for the number of knives, depending on the chop length range required (from 16 to 40 for biomass situations). The machine we tested was fitted with 24 to suit New Zealand conditions.

New Holland has had forward or reverse sharpening as an option for some time and it’s definitely a case of not realising the benefit of having it until you have used it.

Forward sharpening is effective to set the bevel and take the heel off the knives but to hone the sharpest edge, reverse sharpening is the key, and it’s a relatively simple set-up with a hydraulic motor that simply turns the chopping cylinder in reverse for the sharpening cycle and the stone is drawn across the top of the cylinder.

As you expect these days, the sharpening and shear bar setting processes are carried out from the cab and are adjustable.

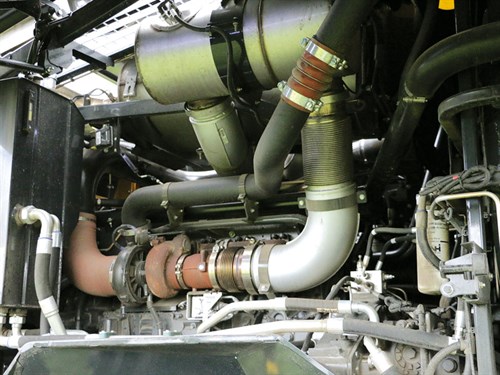

Engine

The five-model 2018 FF Forage cruiser range now uses FPT (Fiat Powertrain Technologies) engines, from 480hp up to a massive 920hp in the newly released FR920. The FR780 we tested uses a six-cylinder 16-litre FPT engine, which so far has proved to be a reliable and economical power plant. It also offers up to a 20 percent reduction in fuel consumption over earlier models.

To meet European Tier 4 final emissions regulations, the engine uses SCR or AdBlue. Diesel tank capacity sits at an impressive 1200 litres and 200 litres of AdBlue, which is sure to keep you on the move. Access to the engine is now even easier than previously, with two huge single-piece side panels that open vertically on gas struts giving unimpeded access.

An Eco engine management mode essentially gives two settings for the electronic throttle: a high rpm range, which can be set between 2100 and 1950rpm (ideal for grass) and a low range that can be set between 1700 and 1850rpm (ideal for maize), offering impressive fuel savings.

The engine management software works within these ranges to ensure optimal operating performance and efficiency. The top transport speed of 40km an hour is possible at just 1200rpm for further fuel savings when moving between jobs.

Cab

The FR780 has the same well-designed, rounded ‘fishbowl’ cab, which was introduced on the first New Holland FR models but with a few subtle changes such as improved access and soundproofing, making it even quieter for the operator. This cab is roomy and gives amazing visibility with almost 360-degree views of the header and the trailer, whether loading on the left, right, or opening up behind.

The driver is positioned in the centre of the machine on a comfortable air ride seat, which is now also upholstered in leather, as is the steering wheel. Provision for passengers is made with a lower seat to try and keep them out of your view.

Under the passenger’s seat is a handy fridge, which fits a 1.5-litre bottle, to keep things chilled on the hottest days.

Climate control air conditioning controls are found on the roof, along with plenty of slots for radios and a CB. The FR780 has also gained even more lights for working at night, with space for up to 20 work lights (most of them being LEDs). It is also useful to see LED lights under the side panels, as these light up the machine when they are open.

Controls

This new design reveals a few changes to the controls. The most notable is that the chute up and down has been moved from the floor to a toggle switch on the right-hand console. This is a great addition, as it gets it out of the way of passengers.

The CommandGrip multi-function lever is the primary control used to control the movement and direction of the FR780. Buttons on top are all within easy reach of your thumb when your hand is on the joystick and includes two flat round buttons that control the movement of the chute and the spout deflector, as well as the header height and level. A second function button operated with your finger on the front of the joystick gives even more control without cluttering up the buttons.

Also worth a mention are the automatic functions built into the controls. These include pre-set header heights and spout positions and a go home button for the spout. The right armrest console includes an outline diagram of the machine, with buttons to control various functions. These are logically laid out to replicate where they would be found, such as 4WD engagement on the rear wheel. The rest of the controls, which are well labelled and easy to use, are on toggle switches arranged along the edge on the console.

The Intelliview monitor will be familiar to those with experience with other New Holland machines. However, even for newcomers, it is clear and easy to see. The customisable run screens can be set to display a wealth of information to the driver without any drama or complications.

Power cruise

Worthy of some explanation is an interesting feature called power cruise. While it definitely takes a little getting used to, this essentially uses the engine management software to control the forward speed of the machine. The driver can set up the target forward speed (usually just slightly faster than the max possible speed) and the minimum engine rpm (somewhere just under 1800rpm).

The machine then controls the forward speed as the engine load from the cutter head changes. This ensures the machine stays at full capacity at all times. In my experience, this works well, in crops such as maize and even grass with heavy and light patches in the row.

Verdict

Having had some experience with the early New Holland FR models, it’s great to see that the company has continued to improve and refine its product.

There is much to like about the New Holland forage harvesters, with industry leading features such as the widest chopping cylinder on the market and reverse sharpening, as well as new features such as the hydraulically opening drop floor on the chopping cylinder and improvements to the cab layout.

Some clever engine management software with Power Cruise and Eco engine management mode delivers exceptional productivity and efficiency through fuel savings. The New Holland forage harvester range is well worth consideration, as sometimes you don’t realise what you’re missing until you have tried it.

New Holland FR780 Forage Cruiser Specifications

| Engine | FPT Cursor 16 |

| Emissions standard | Tier 4 Final using AdBlue |

| Cylinders | Six |

| Capacity | 15.9L |

| Rated max power | 775hp |

| Fuel capacity | 1200L |

| Transmission | Four ranges |

| Max speed | 40km/hr |

| Feeding | HydroLoc drive with infinite adjustment |

| Knives | 2x8, 2x10, 2x12, 2x16, 2x20 |

| Cutterhead cylinder width | 884mm |

| Cutterhead cylinder diameter | 710mm |

| Weight | 13,060kg |

Pluses

- Widest feed rollers and chopping cylinder on the market for higher throughput

- Sectional metal detection for easier metal and rock detection

- Forward and reverse sharpening

- Impressive 16-litre FPT engine with a massive 775hp uses only AdBlue to meet Tier 4 final emissions

- Updated cab and controls layout for eaiser operation

- PowerCruise and Eco engine management for high output and better economics

Minuses

- Stactic causes dust to stick to the pannels where they are glued to the frame

Keep up to date in the industry by signing up to Farm Trader's free newsletter or liking us on Facebook

.jpg)